LED Disk Build Log

Images showing how a 96-LED artefact was built to instantiate the system developed for this project…

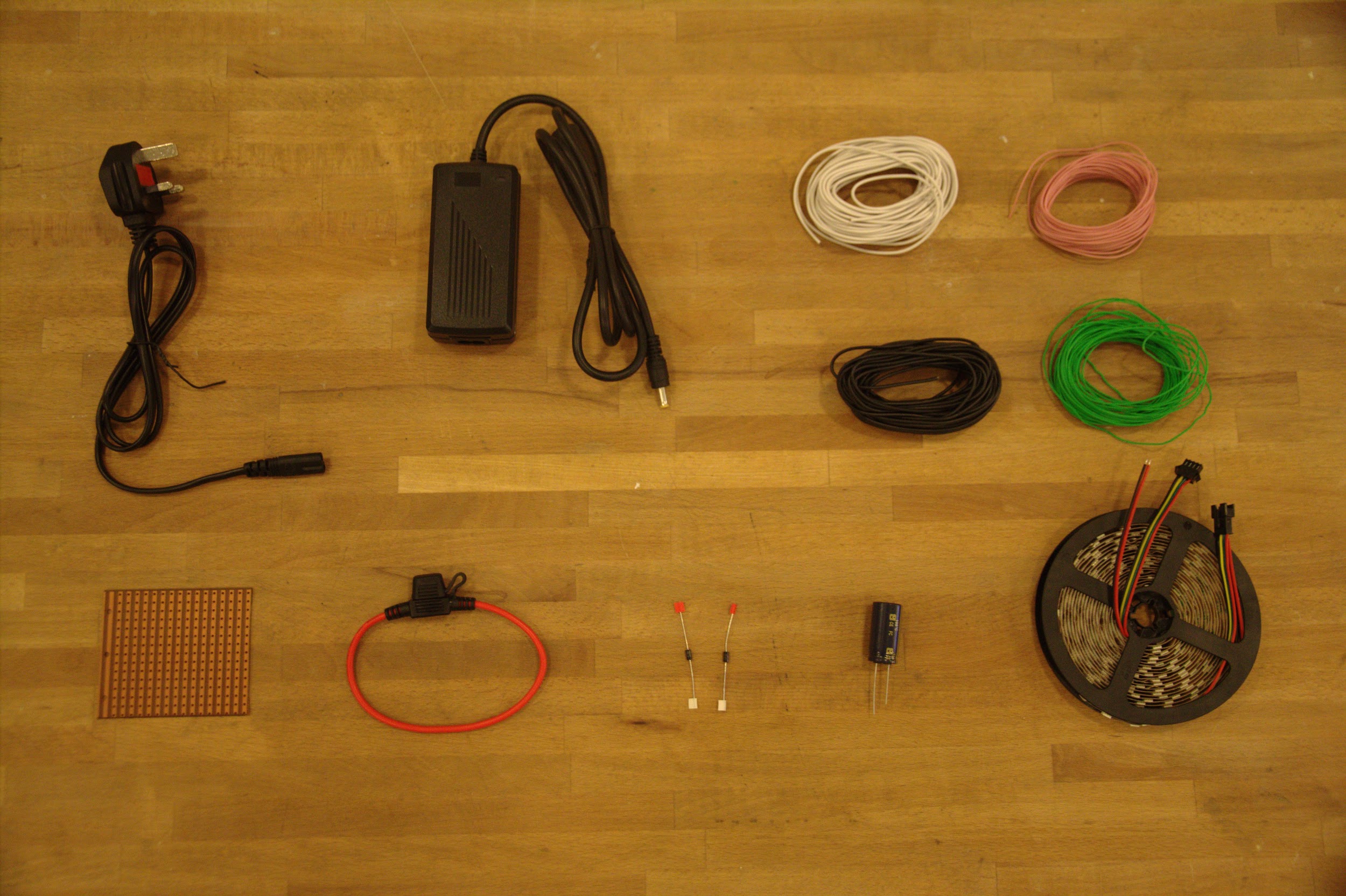

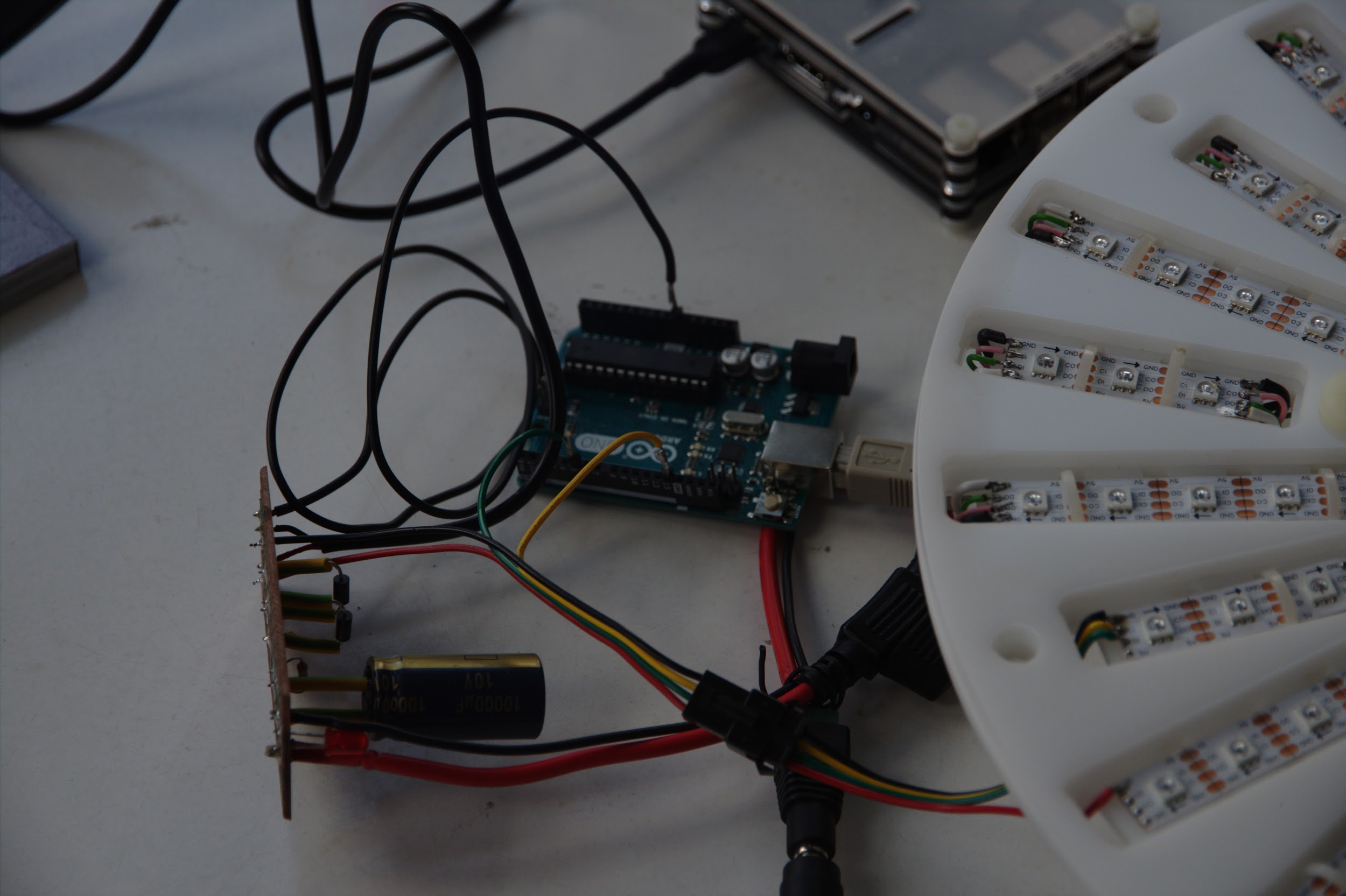

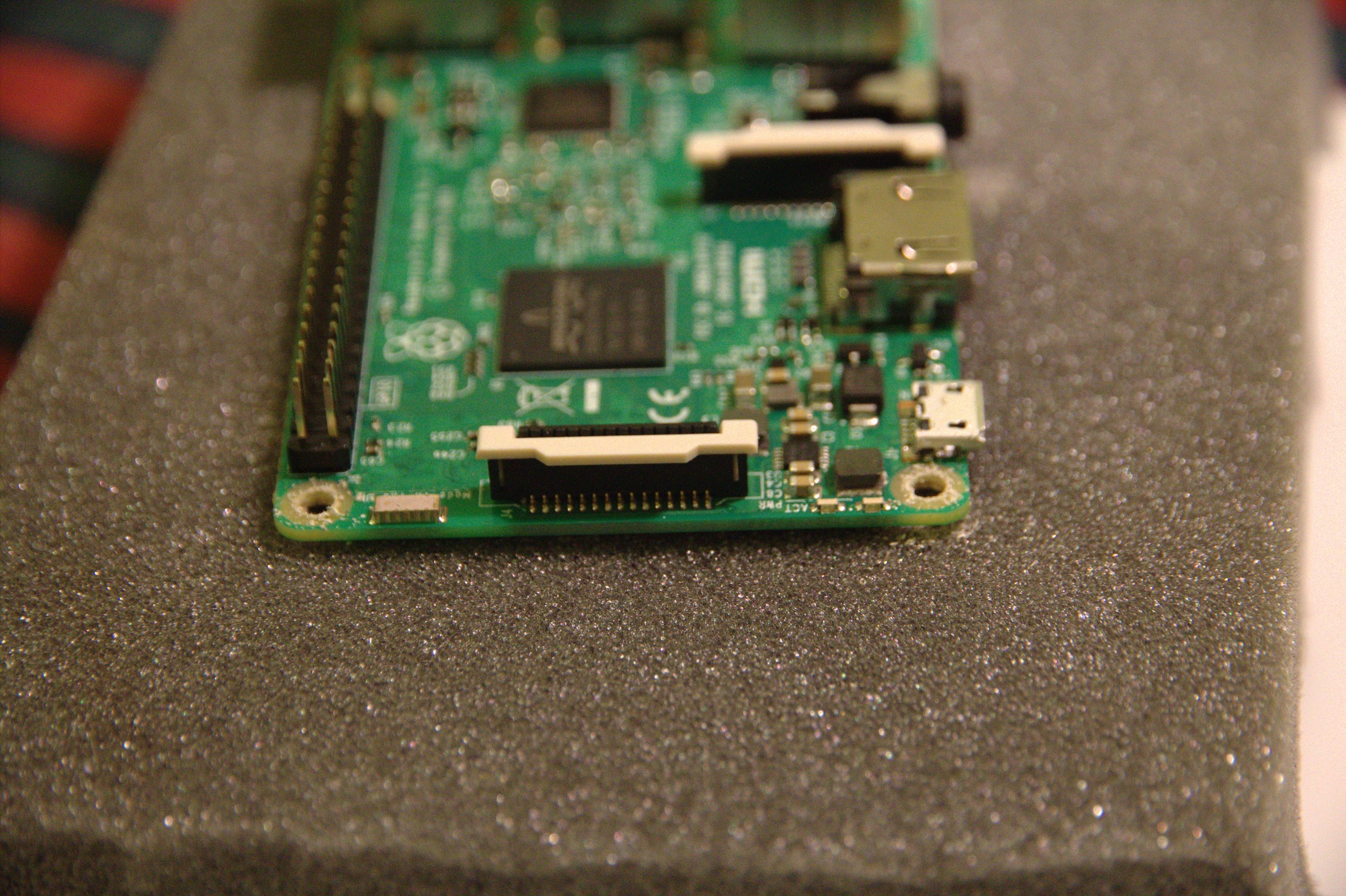

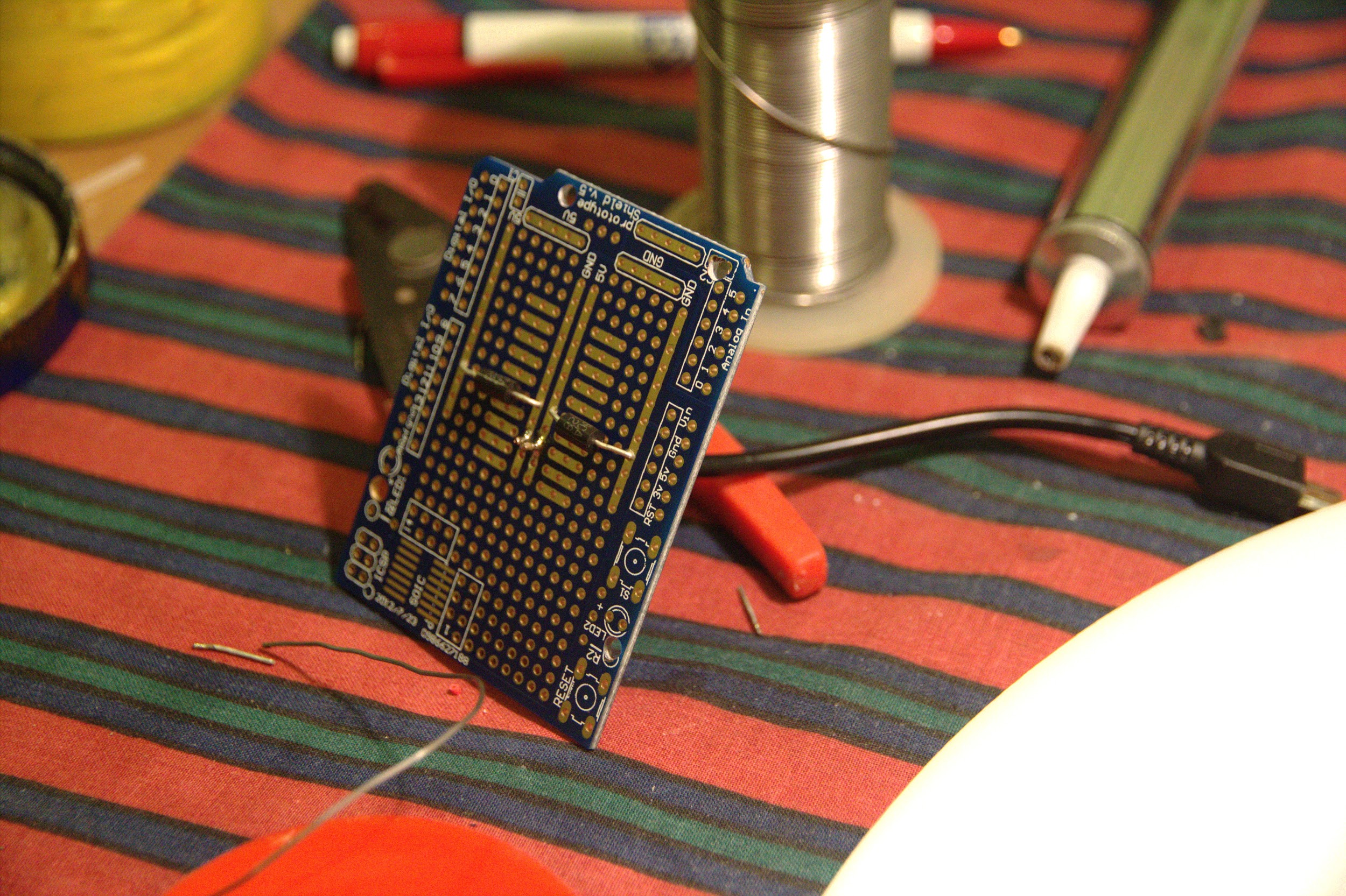

Prototype components: 5V 8A DC power adaptor, stripboard, wire, 7A automotive fuse w/ fuse

holder, 2 voltage regulators, 10,000μF capacitor and a 60LED/metre roll of addressable

APA102s, (not pictured:) Raspberry Pi, Arduino, USB cables, terminal block to connect the

power supply to, and a single LED + fuse to indicate power

Prototype components: 5V 8A DC power adaptor, stripboard, wire, 7A automotive fuse w/ fuse

holder, 2 voltage regulators, 10,000μF capacitor and a 60LED/metre roll of addressable

APA102s, (not pictured:) Raspberry Pi, Arduino, USB cables, terminal block to connect the

power supply to, and a single LED + fuse to indicate power

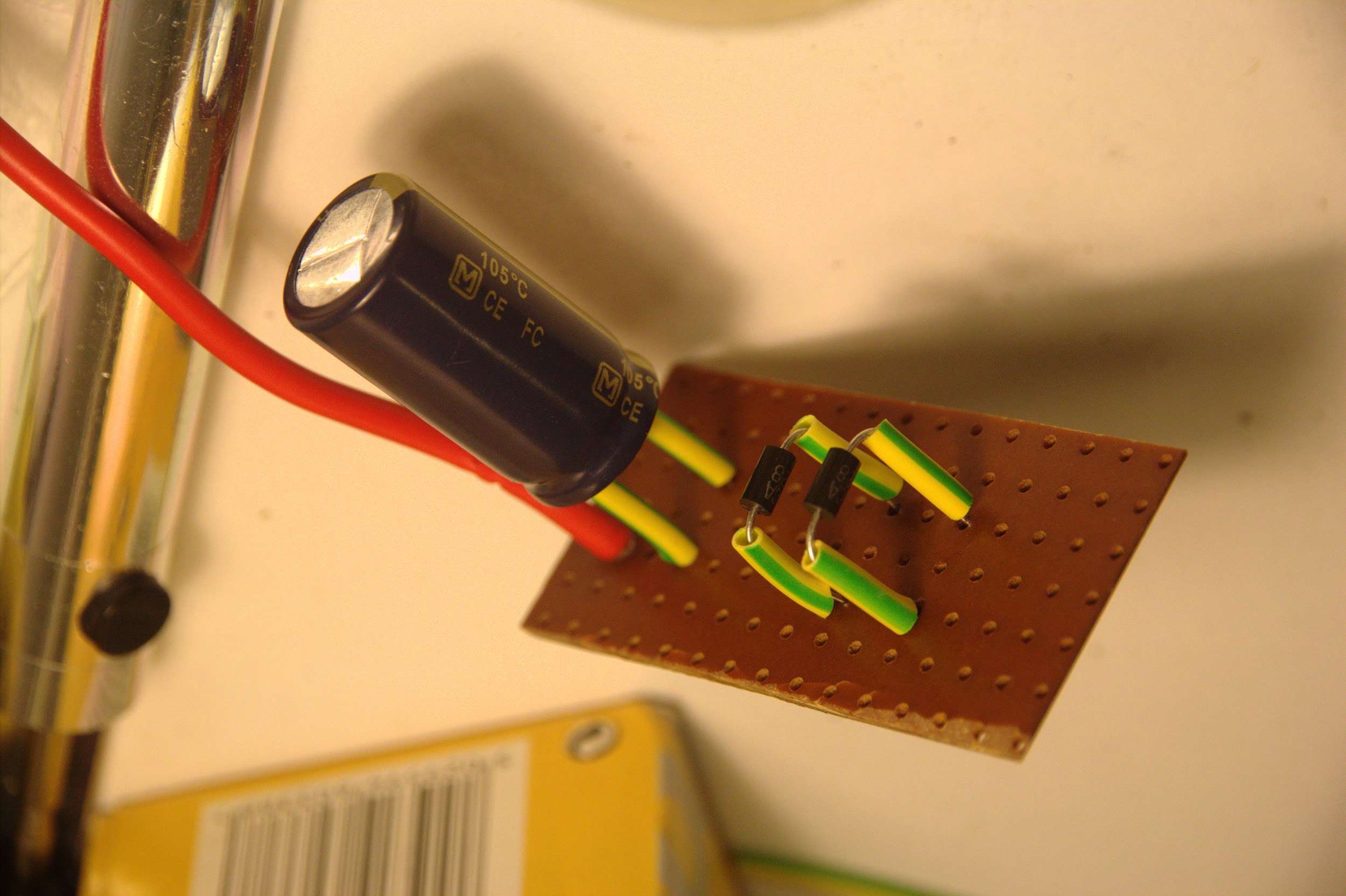

Voltage regulators and the capacitor soldered at a distance from the stripboard so they can be

easily desoldered to use in the final piece, with insulating sleeving to prevent a short circuit

Voltage regulators and the capacitor soldered at a distance from the stripboard so they can be

easily desoldered to use in the final piece, with insulating sleeving to prevent a short circuit

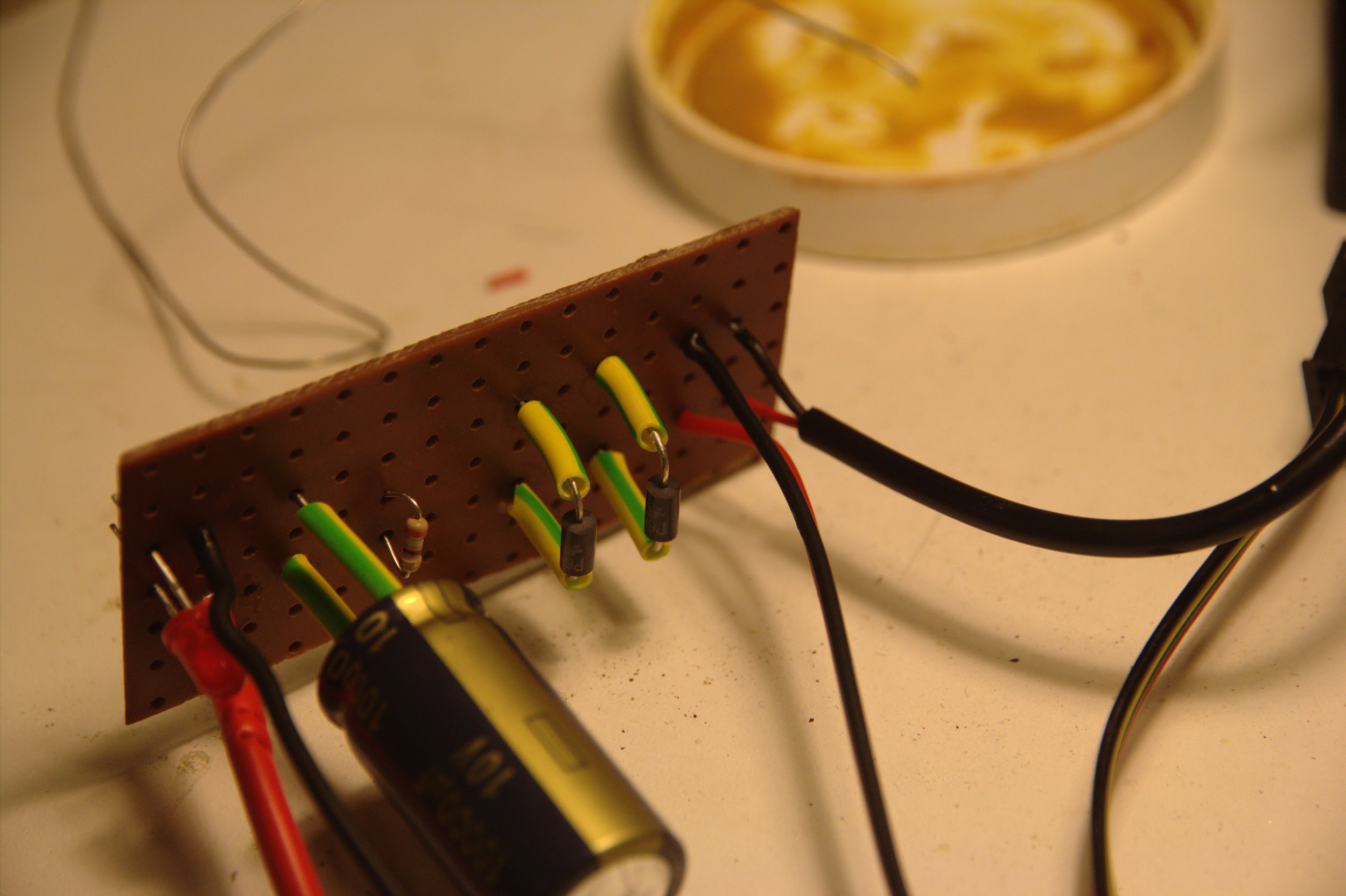

Testing power delivery with an LED on the splitboard indicating live rails

Testing power delivery with an LED on the splitboard indicating live rails

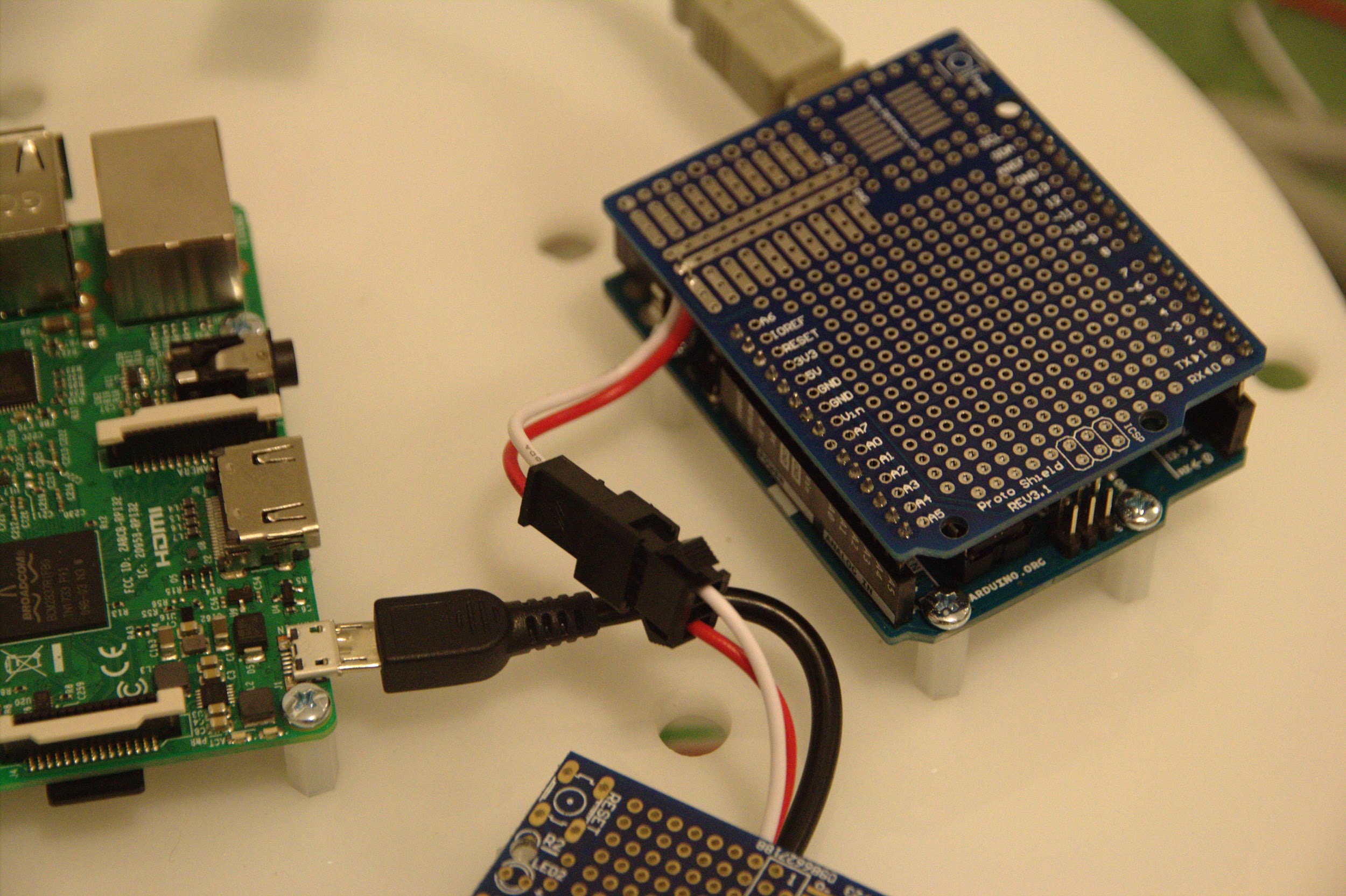

+5V and ground pairs (soldered on the right side of the stripboard) connecting to the RPi

MicroUSB and APA102 connector

+5V and ground pairs (soldered on the right side of the stripboard) connecting to the RPi

MicroUSB and APA102 connector

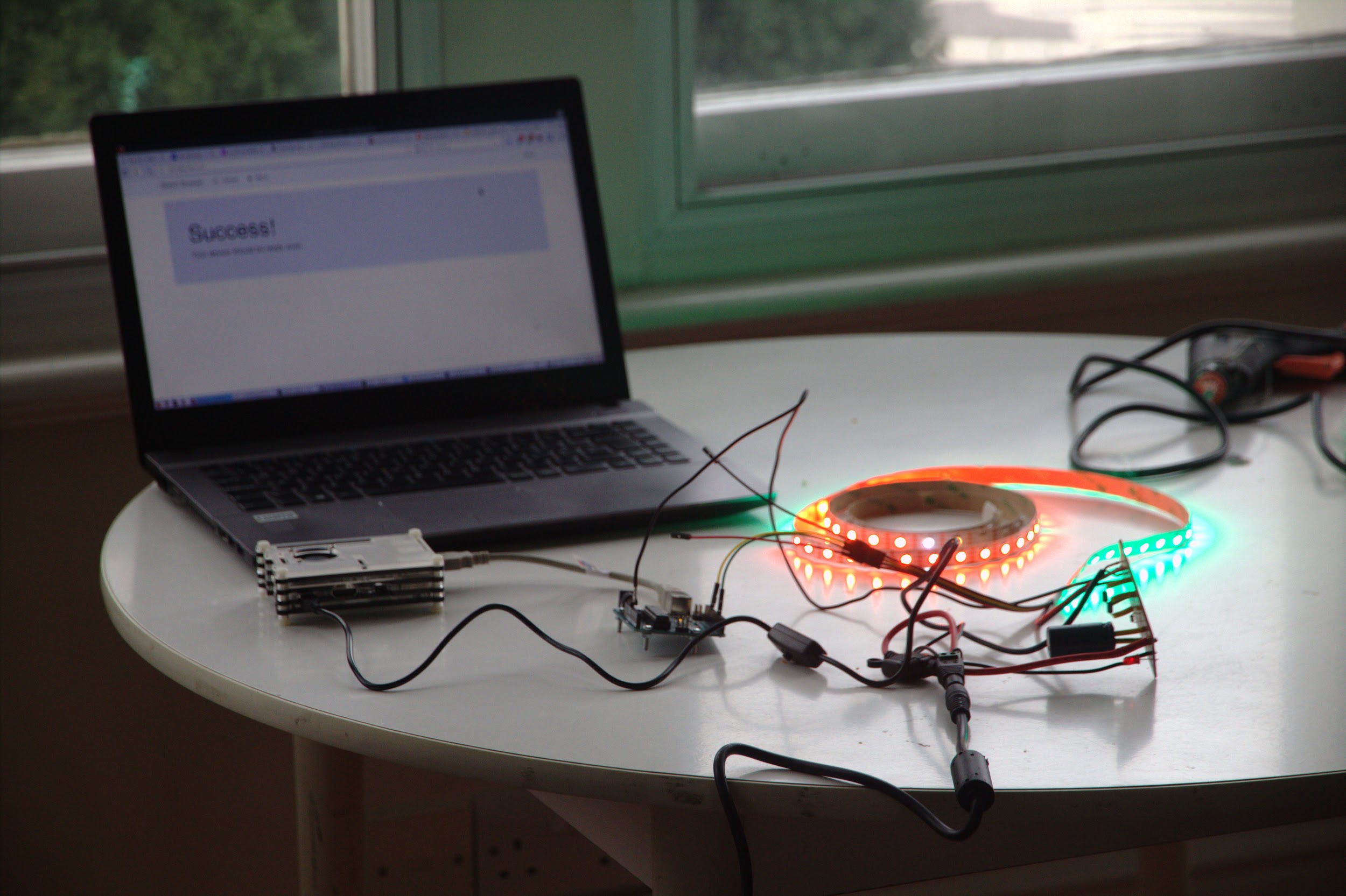

“Success!” with the strip lighting up after connecting the prototype splitboard, LEDs, Raspberry

Pi and Arduino together then compiling and uploading APA102 Arduino code

“Success!” with the strip lighting up after connecting the prototype splitboard, LEDs, Raspberry

Pi and Arduino together then compiling and uploading APA102 Arduino code

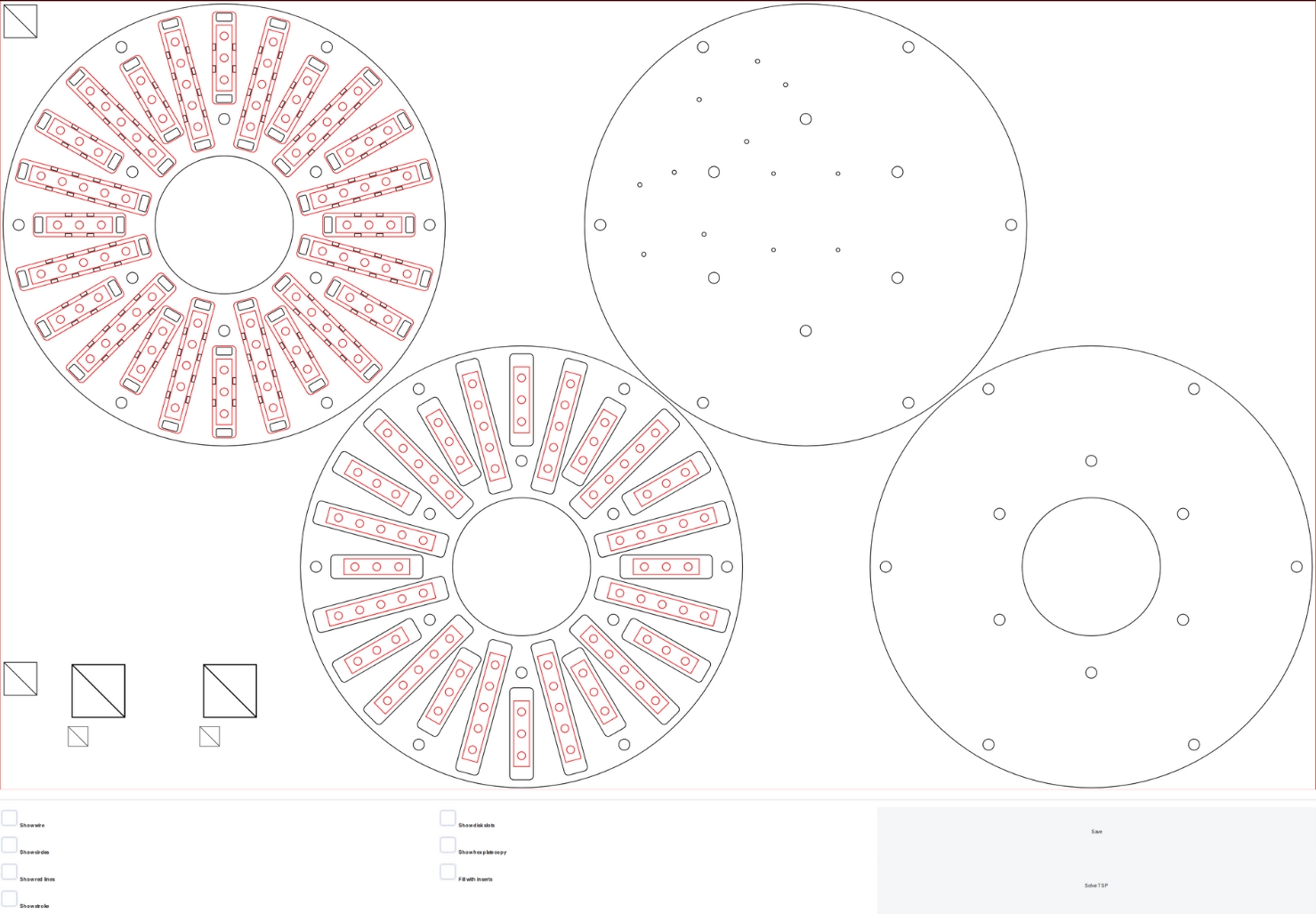

Web application developed for the final design showing the SVG above HTML inputs that

provide GUI access to basic functions

Web application developed for the final design showing the SVG above HTML inputs that

provide GUI access to basic functions

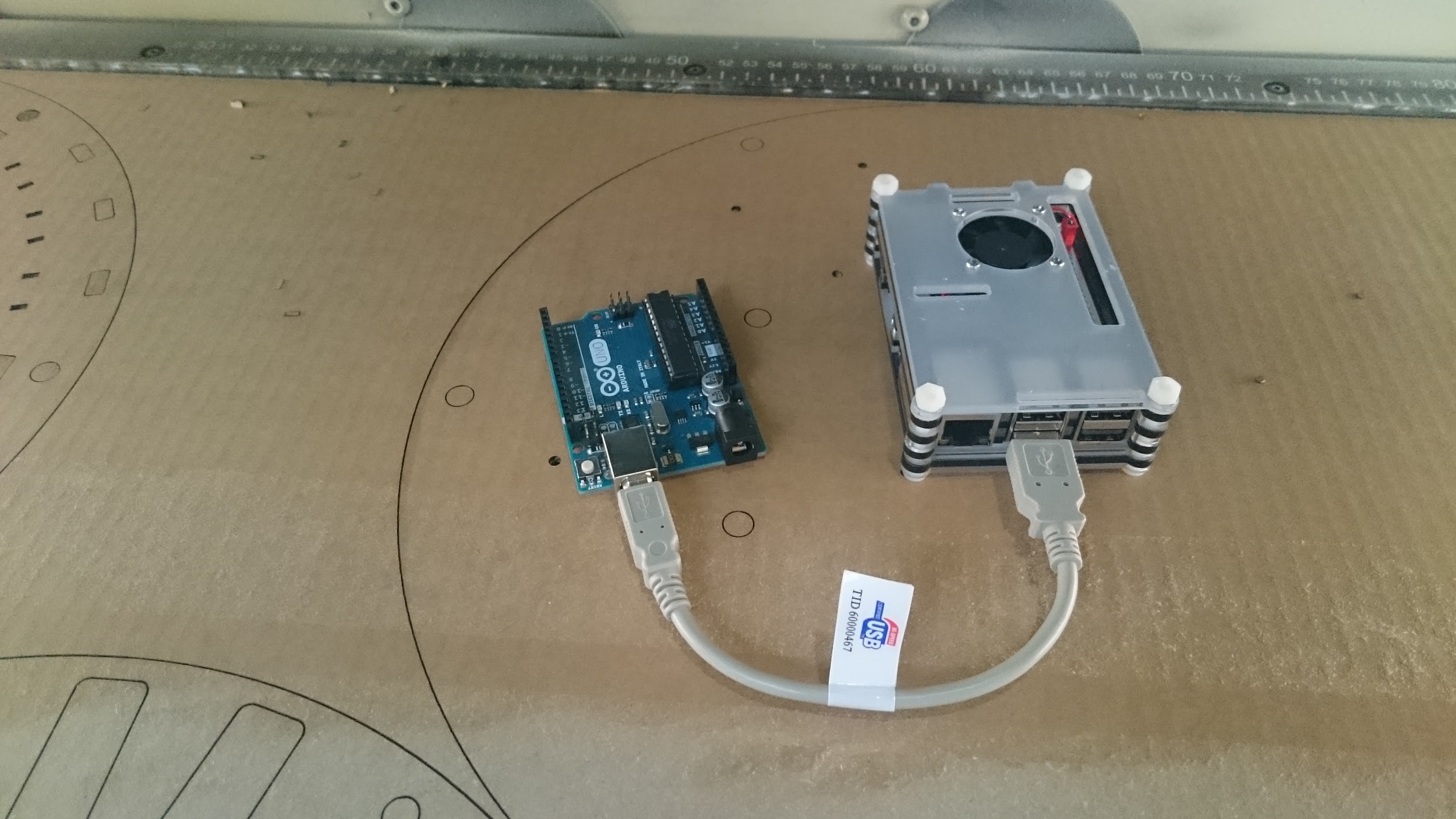

Laser cutting machine (centre) with the computer used to control it (right) and the project

development laptop (left)

Laser cutting machine (centre) with the computer used to control it (right) and the project

development laptop (left)

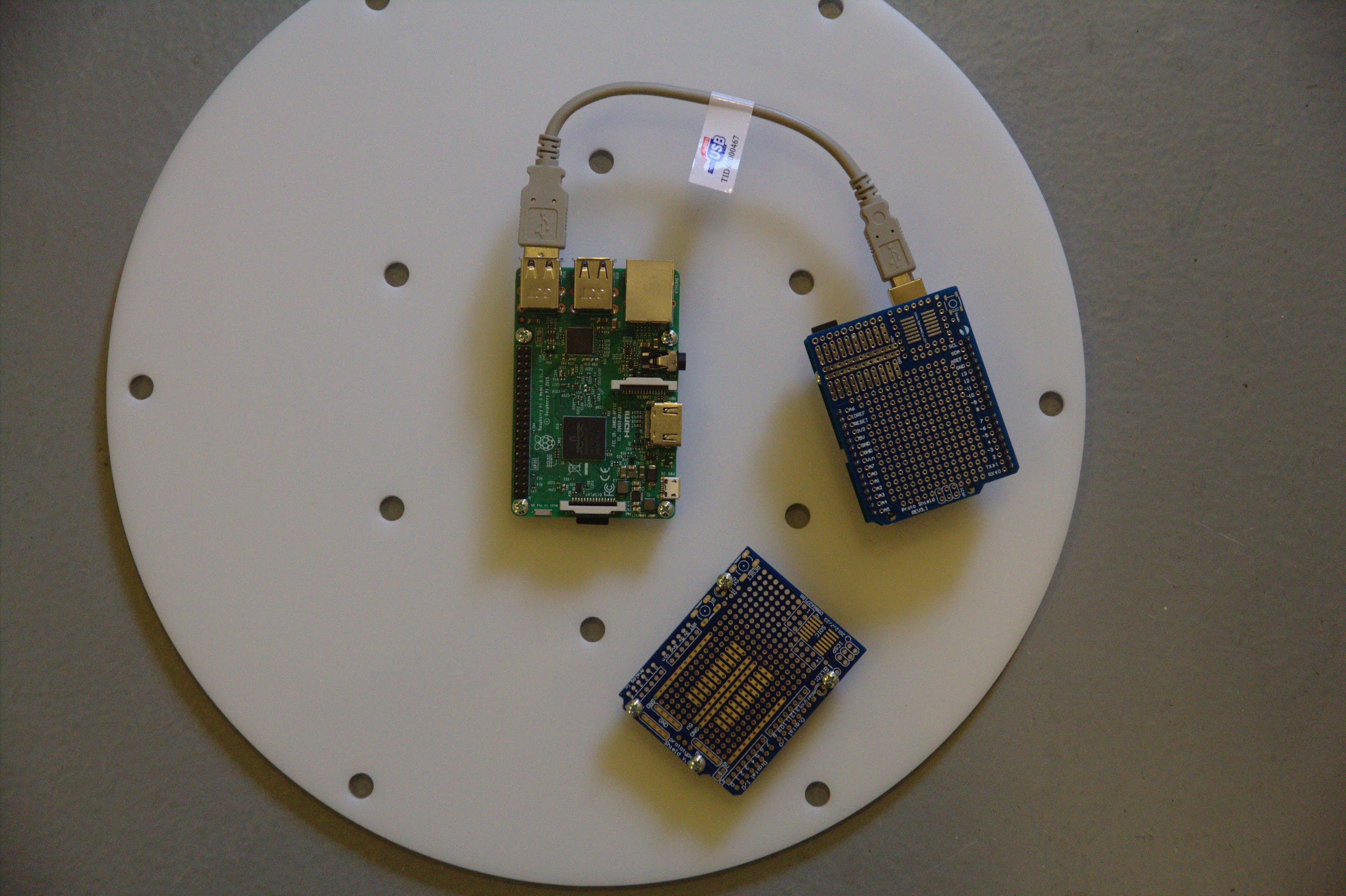

Checking the design’s scaling and measurement on cardboard using the Arduino and

Raspberry Pi

Checking the design’s scaling and measurement on cardboard using the Arduino and

Raspberry Pi

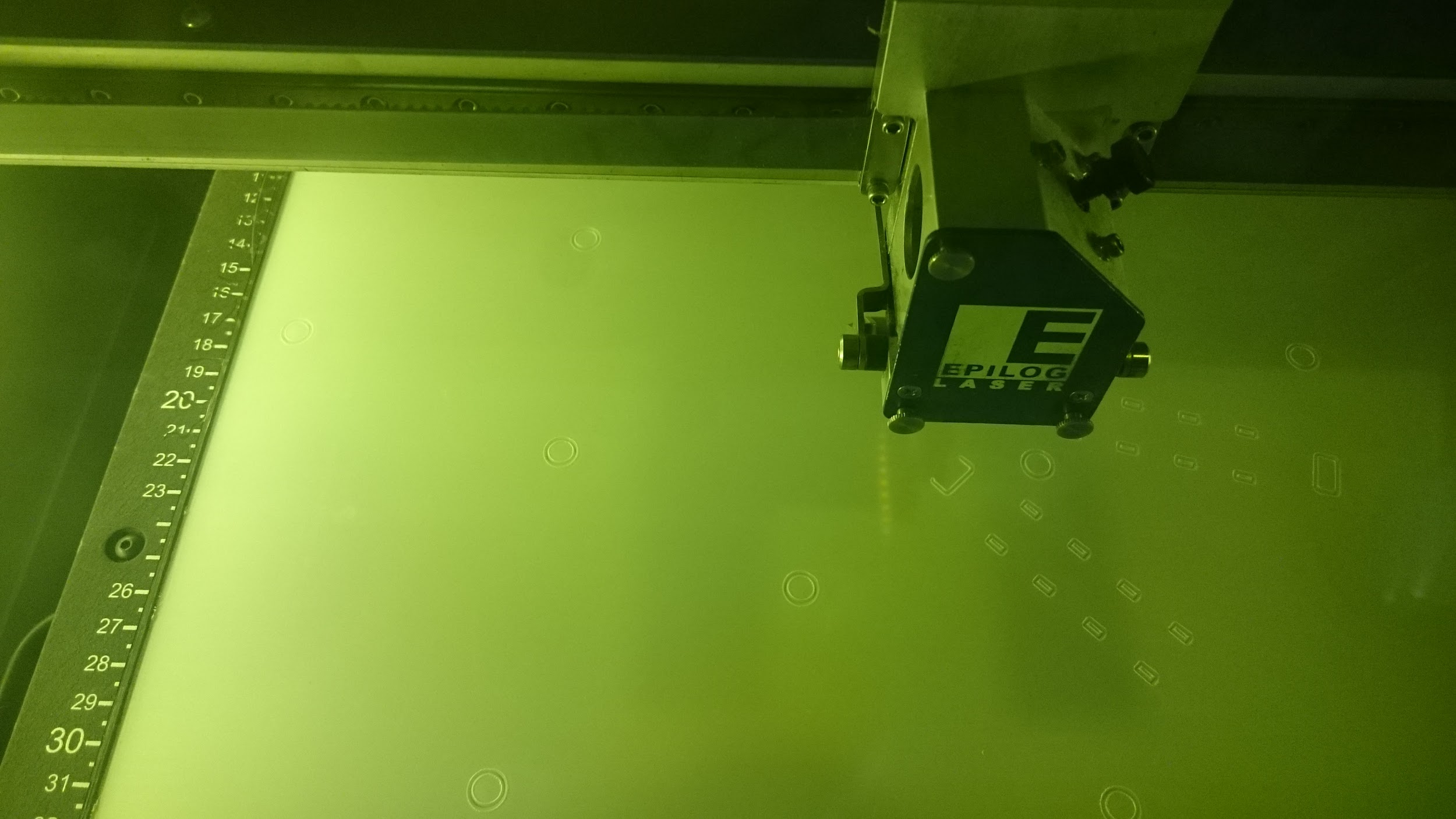

The first cable and bolt holes being laser cut out of Perspex

The first cable and bolt holes being laser cut out of Perspex

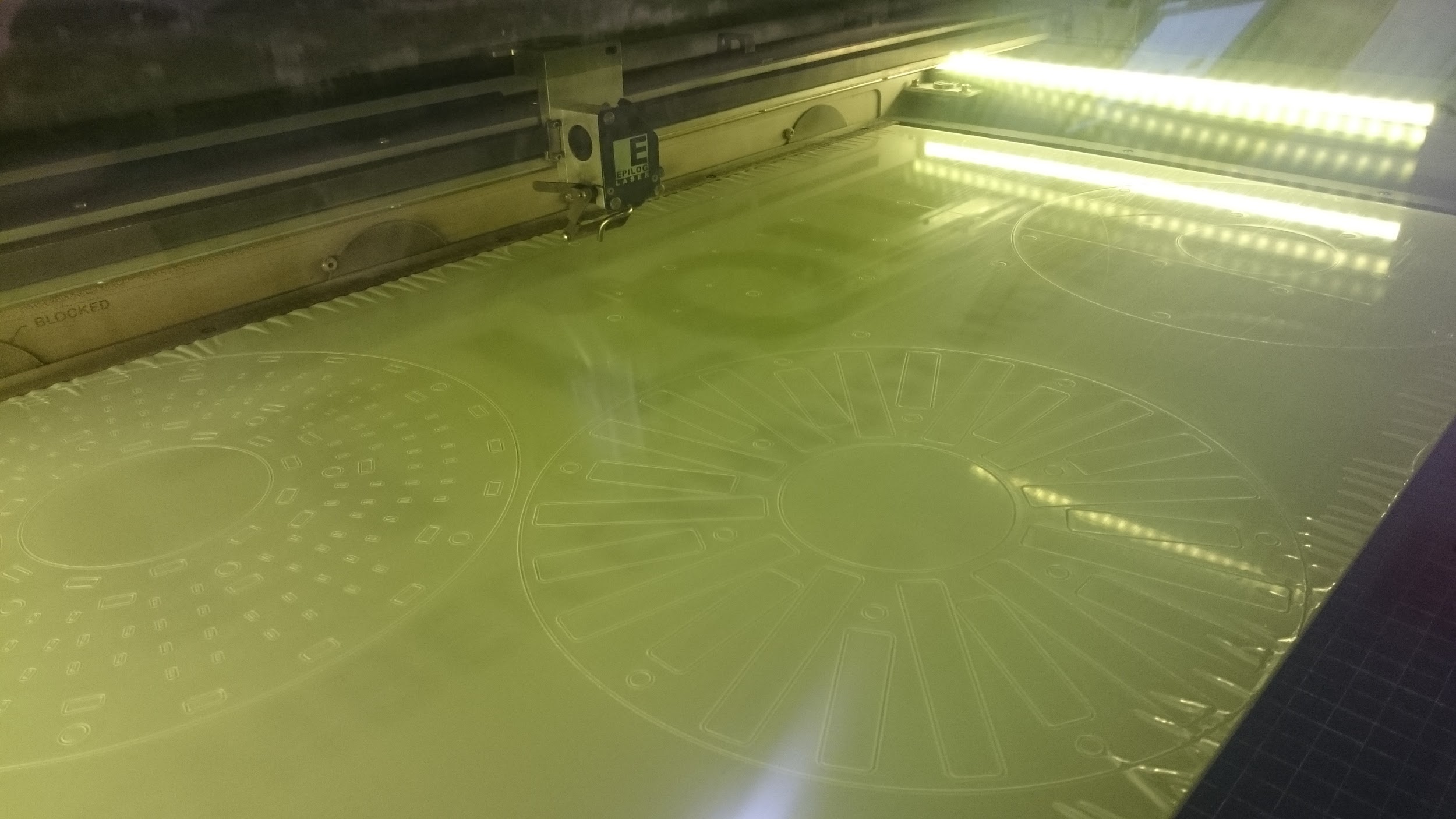

Towards the end of the laser cut process, it took over an hour in total

Towards the end of the laser cut process, it took over an hour in total

Peeling protective film off both sides of the Perspex

Peeling protective film off both sides of the Perspex

Sharp edges were leftover after detaching some pieces of acrylic (later filed down for safety)

Sharp edges were leftover after detaching some pieces of acrylic (later filed down for safety)

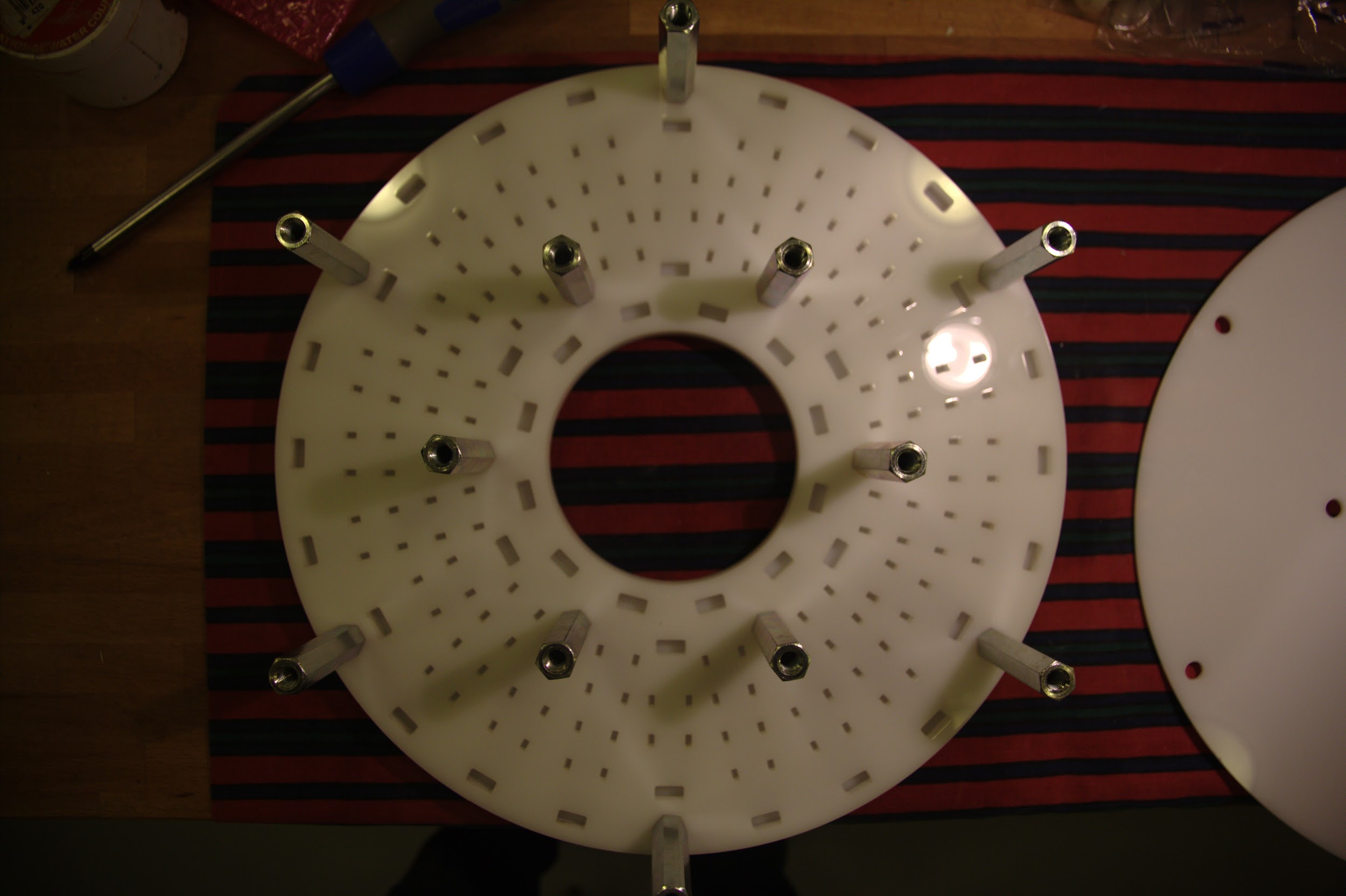

Checking the bolts fit securely through 3 pieces of Perspex into the spacers

Checking the bolts fit securely through 3 pieces of Perspex into the spacers

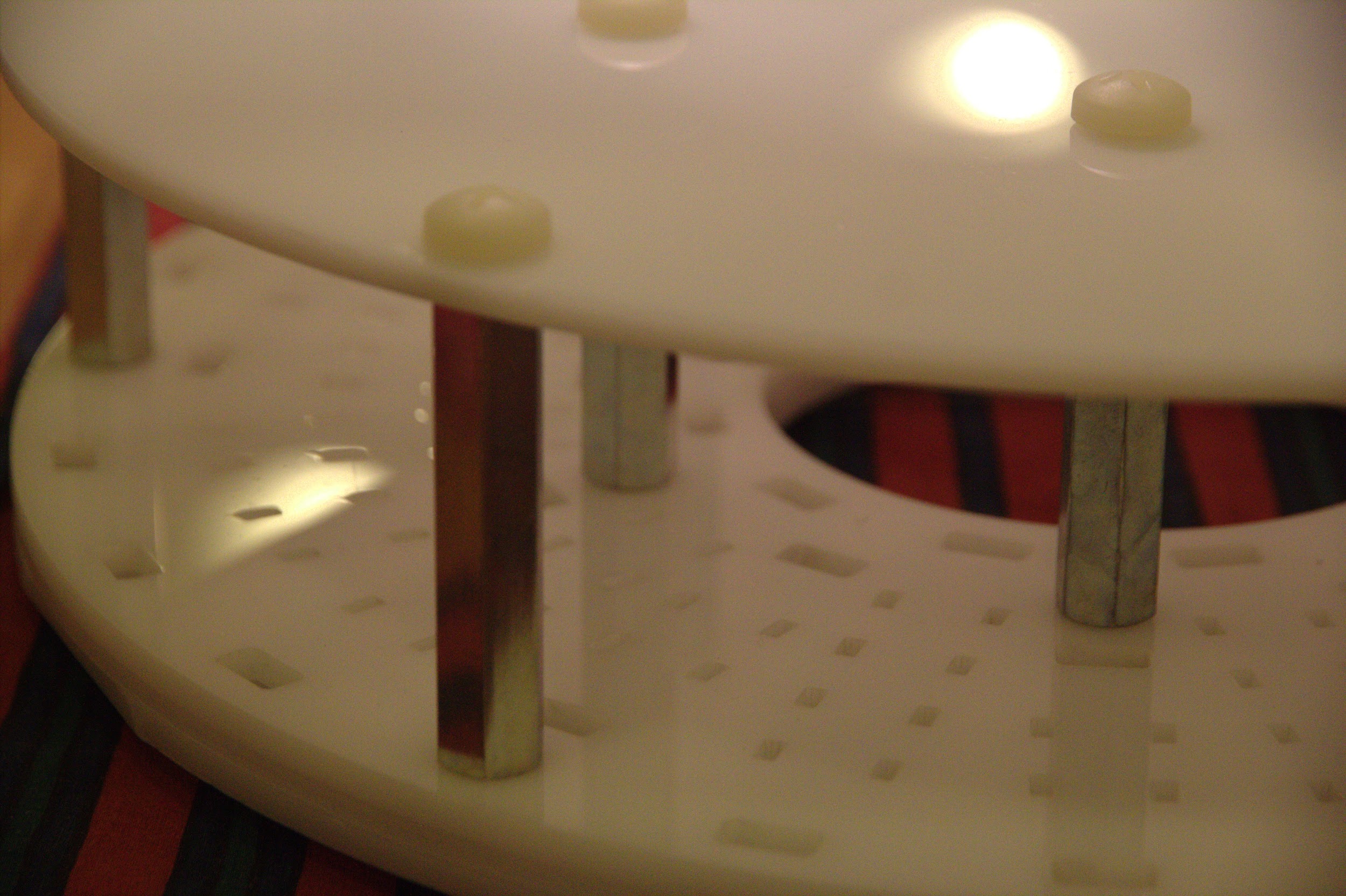

Bolts going through the single-layer side of Perspex screwed deeper into the spacers, resulting

in noticeably higher resistance/friction

Bolts going through the single-layer side of Perspex screwed deeper into the spacers, resulting

in noticeably higher resistance/friction

Sawing bolts to a shorter length to go through the single-layer side of Perspex

Sawing bolts to a shorter length to go through the single-layer side of Perspex

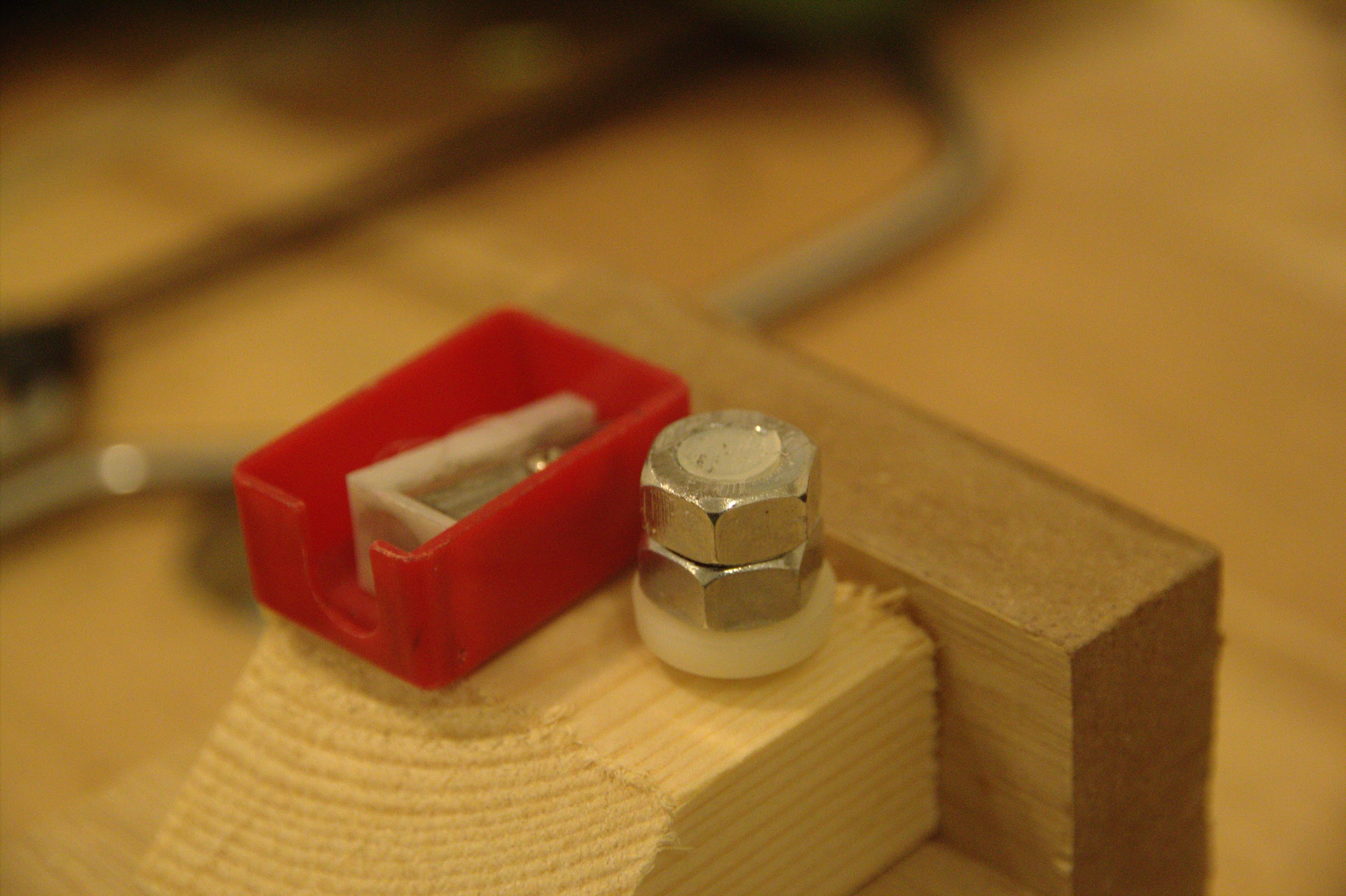

The bolts’ thread is initially damaged by the sawing process, unscrewing the nuts afterwards

helps to restore the original grooves

The bolts’ thread is initially damaged by the sawing process, unscrewing the nuts afterwards

helps to restore the original grooves

The shortened bolts secure into the spacers more easily

The shortened bolts secure into the spacers more easily

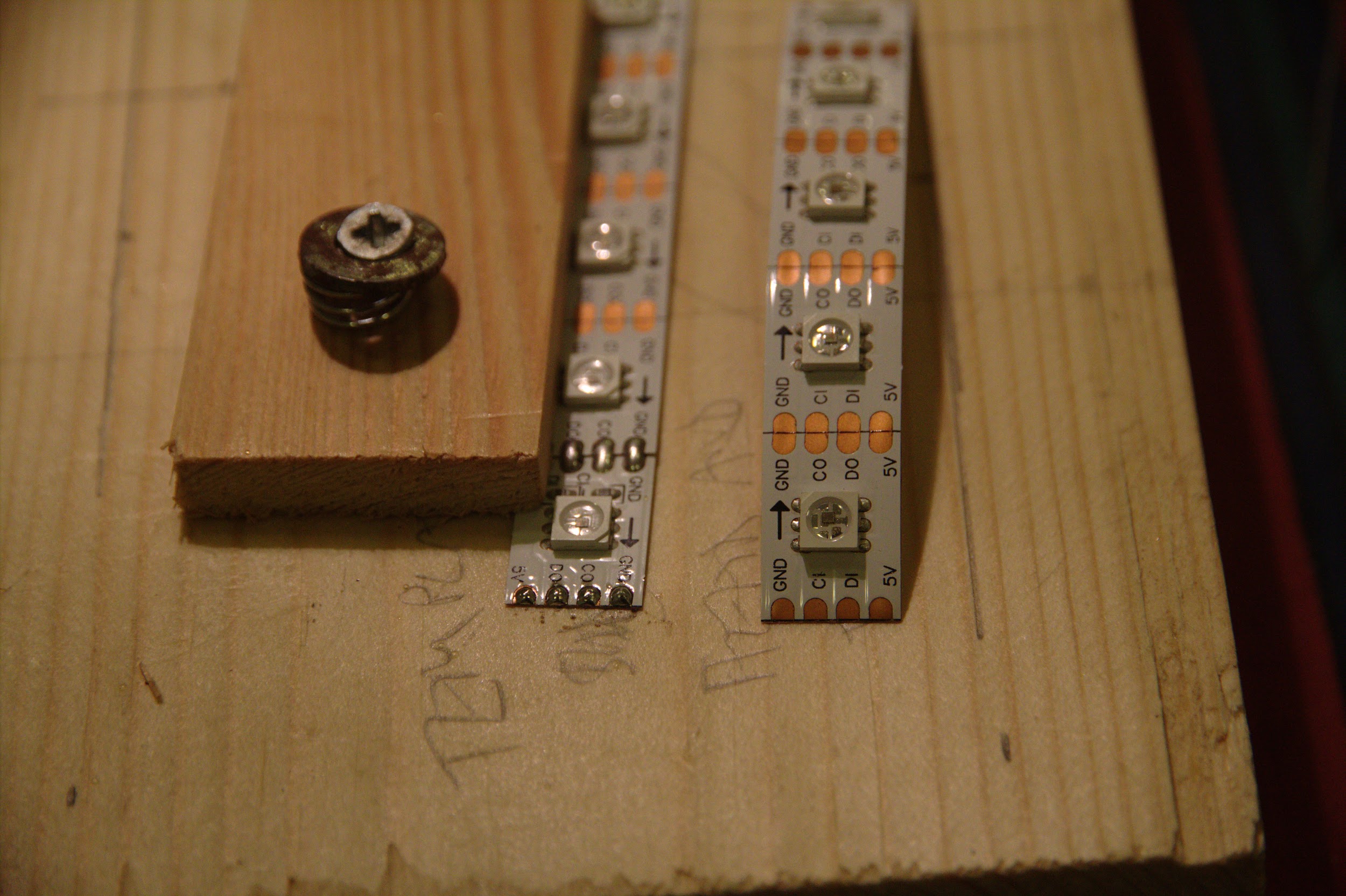

Cutting the first strip of 5 LEDs off the PCB reel

Cutting the first strip of 5 LEDs off the PCB reel

Comparison of tinned and untinned connections (left and right respectively), it helps to prepare

these on a rig that is less fiddly than the Perspex strip holder

Comparison of tinned and untinned connections (left and right respectively), it helps to prepare

these on a rig that is less fiddly than the Perspex strip holder

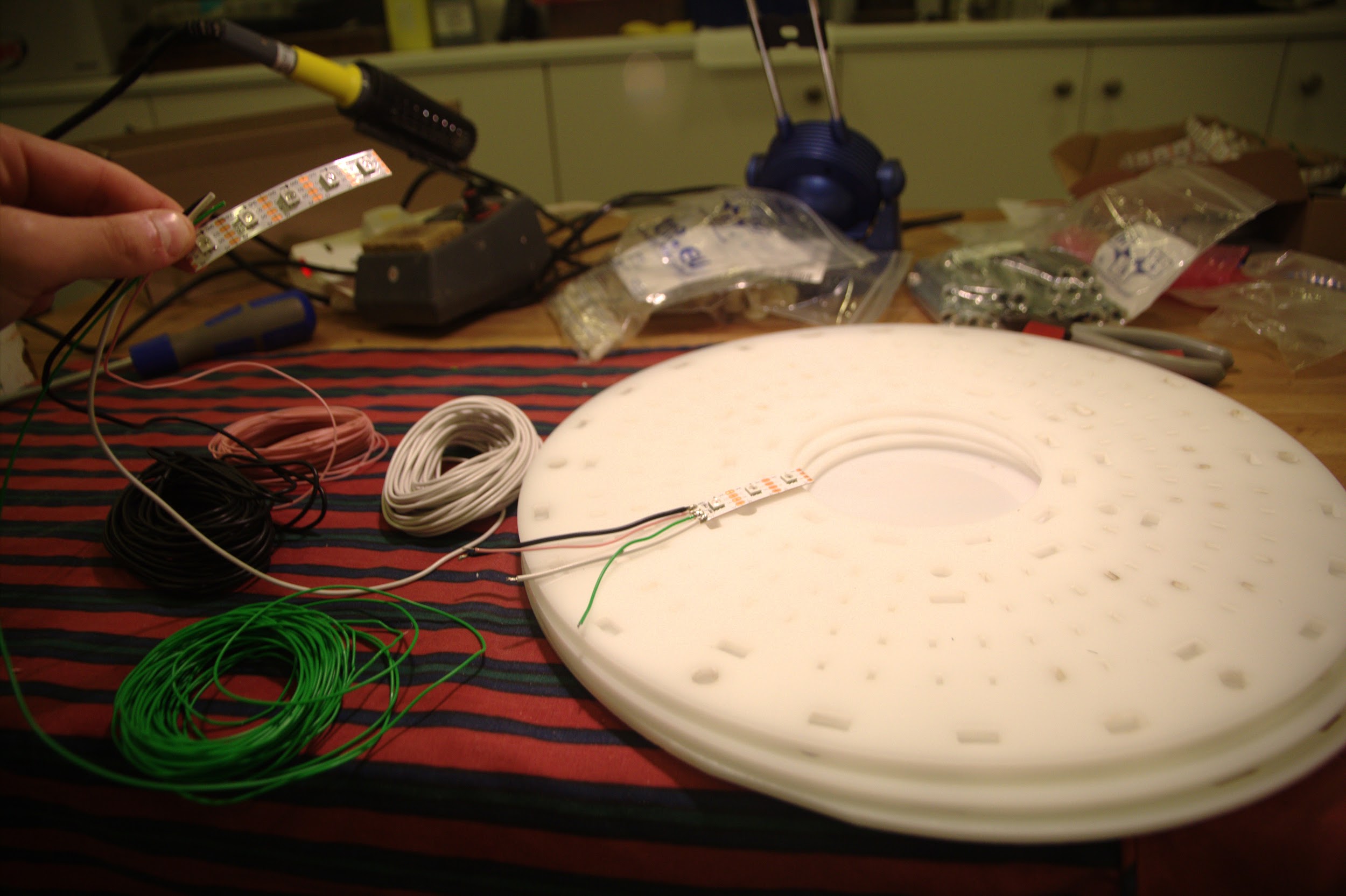

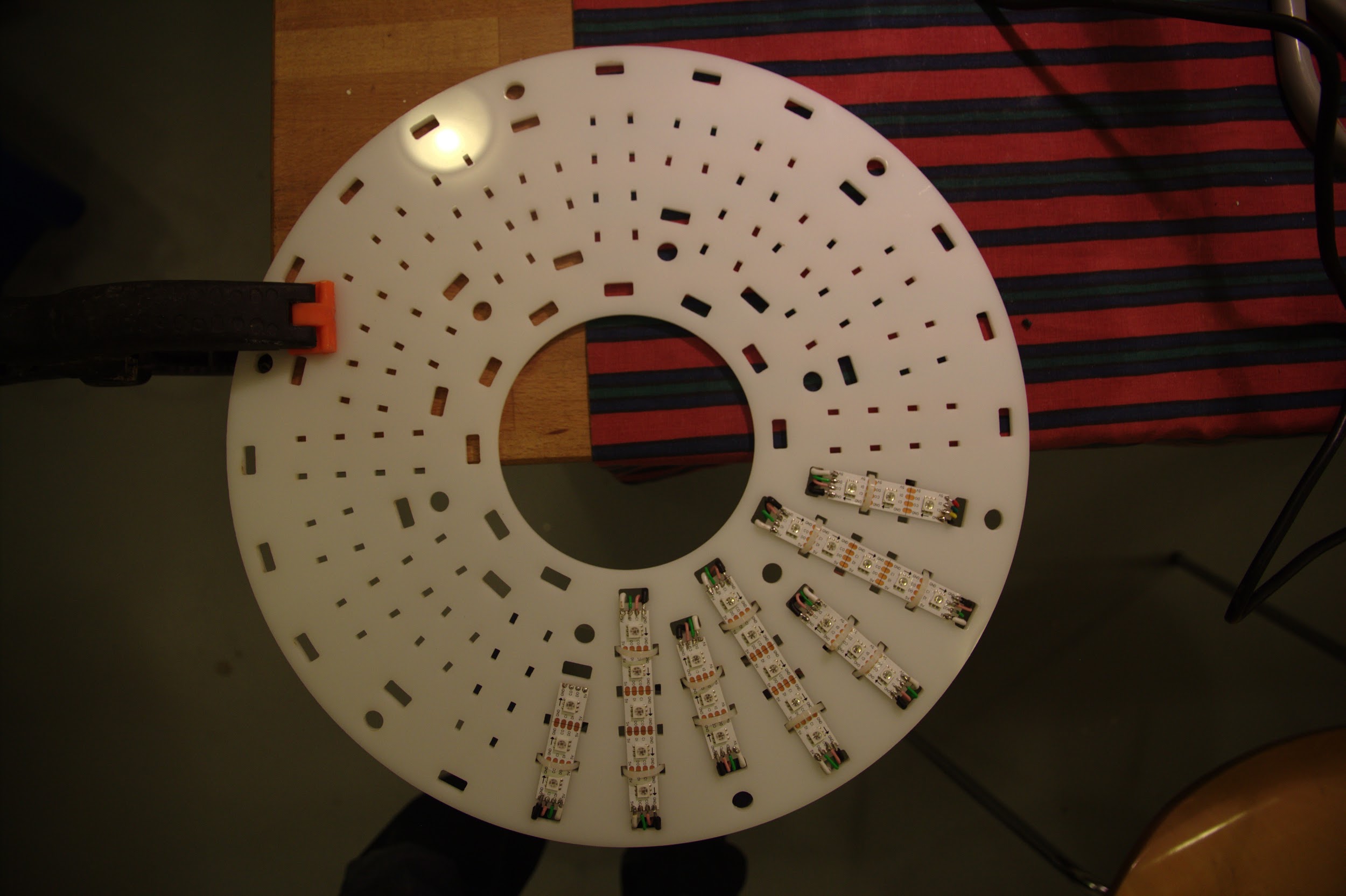

A small number of strips were attached to begin with, so the technique could be improved

A small number of strips were attached to begin with, so the technique could be improved

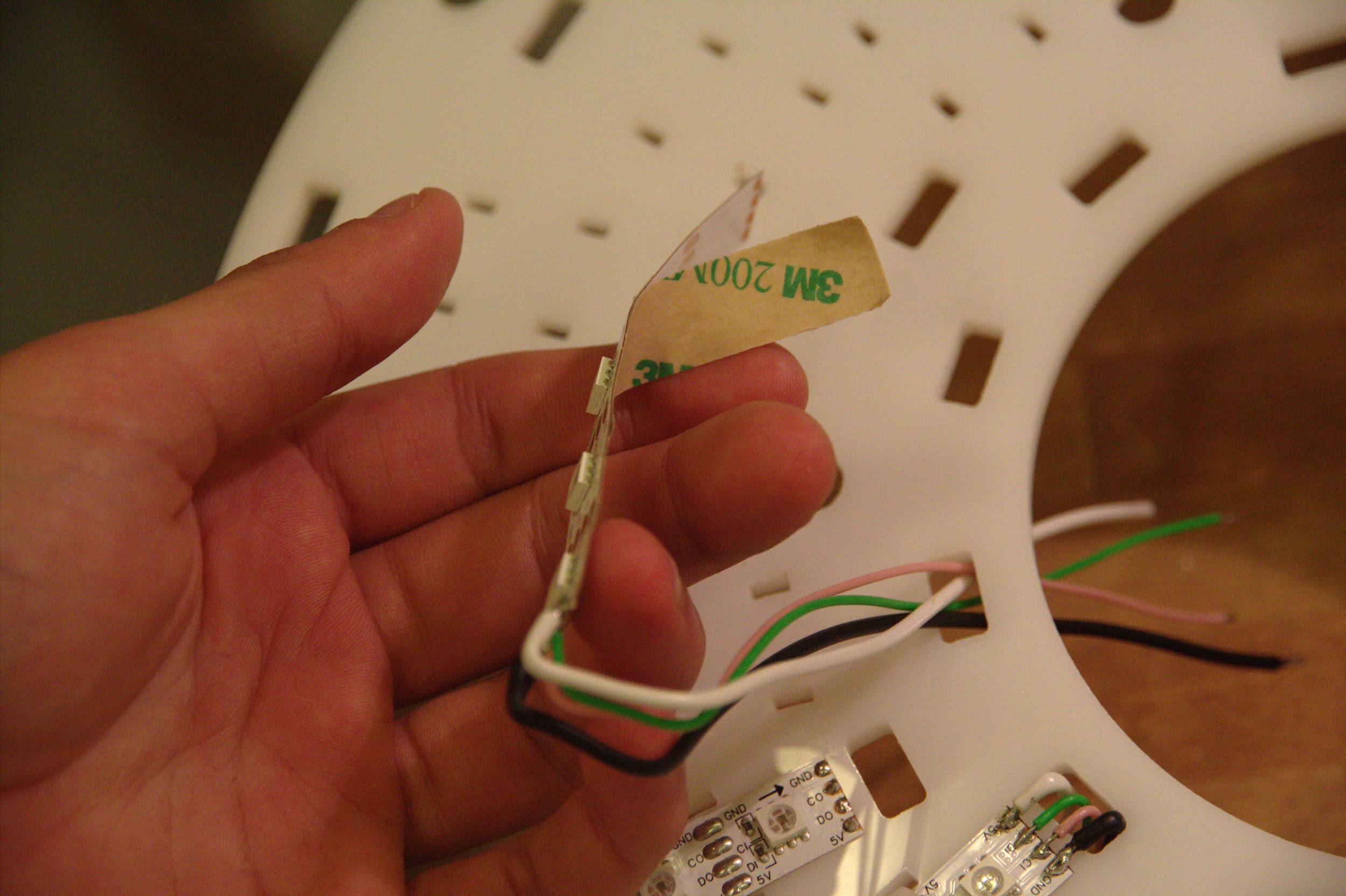

Peeling adhesive tape off the bottom of the strip in order to stick them to the Perspex

Peeling adhesive tape off the bottom of the strip in order to stick them to the Perspex

After the adhesive, zip-ties secure the strips to the Perspex and help manage the wires below

After the adhesive, zip-ties secure the strips to the Perspex and help manage the wires below

Setup to cut and pre-solder LED strip and wire for more segments of the physical piece

Setup to cut and pre-solder LED strip and wire for more segments of the physical piece

Prepared segments after stripping the wires, twisting the stranded ends to avoid fraying and

tinning the connections

Prepared segments after stripping the wires, twisting the stranded ends to avoid fraying and

tinning the connections

The LED-bearing Perspex after a quarter of the strips were attached

The LED-bearing Perspex after a quarter of the strips were attached

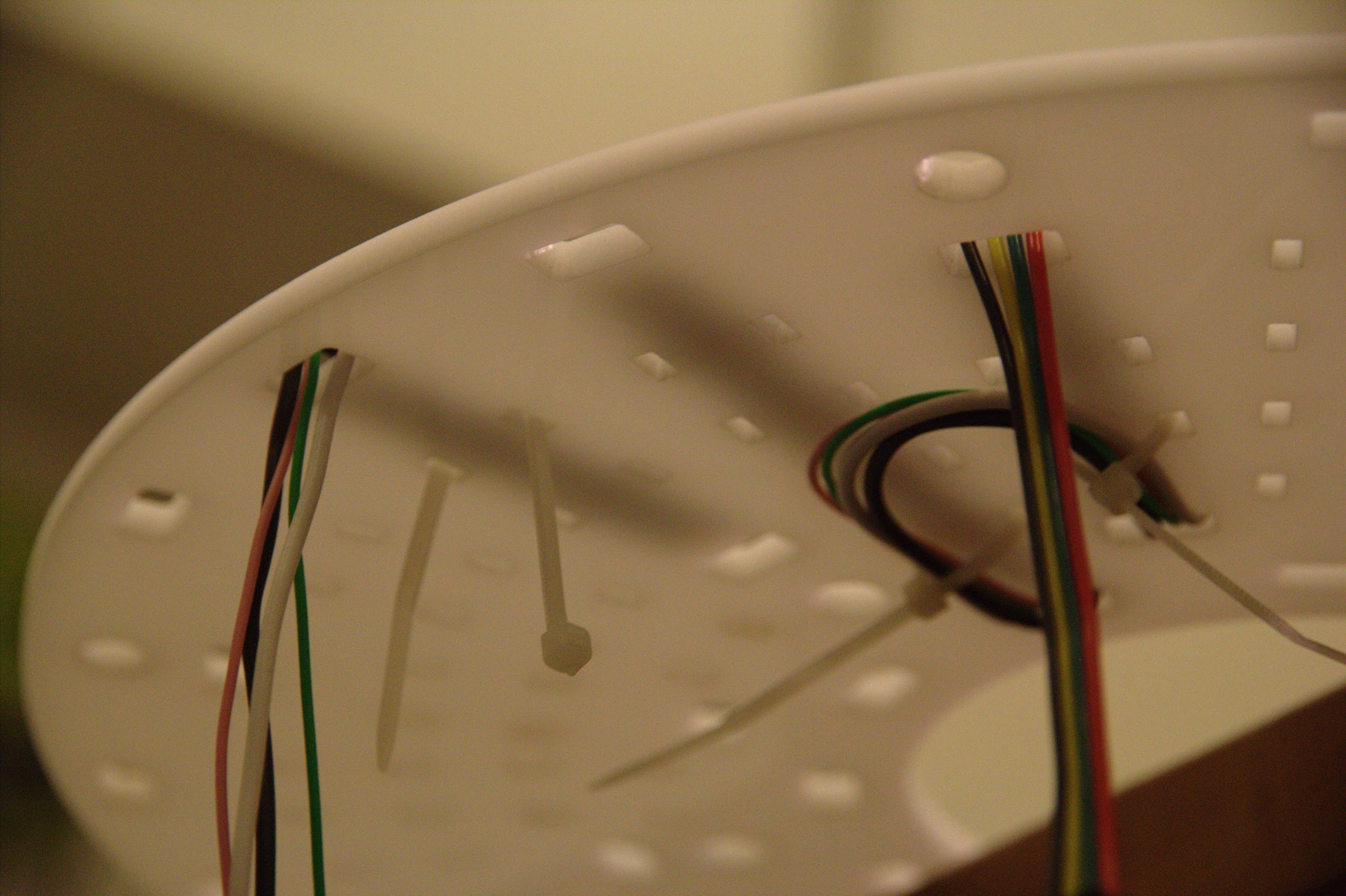

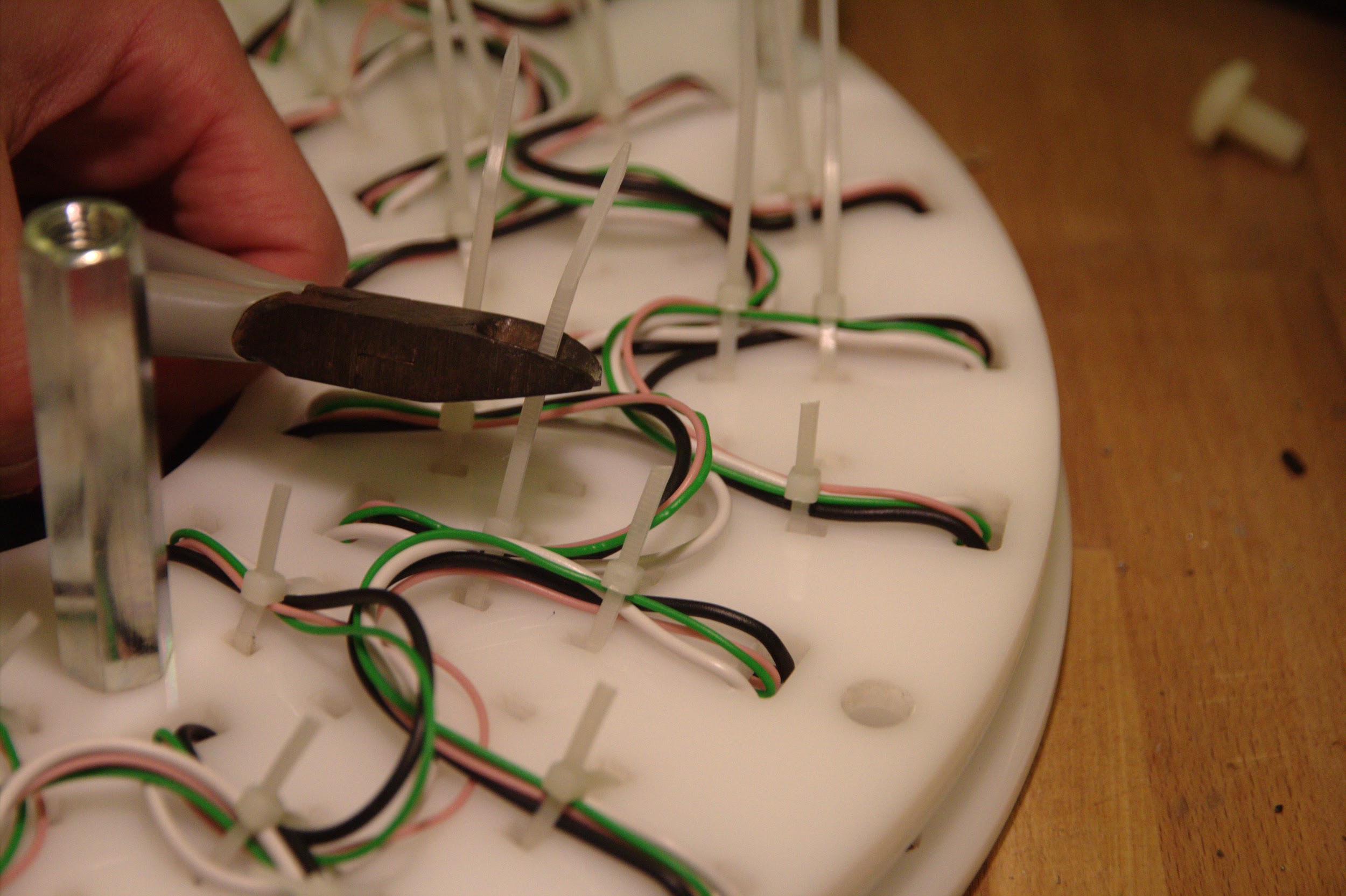

Wires linking each segment of LED strip to the next are routed through zip ties below the acrylic

Wires linking each segment of LED strip to the next are routed through zip ties below the acrylic

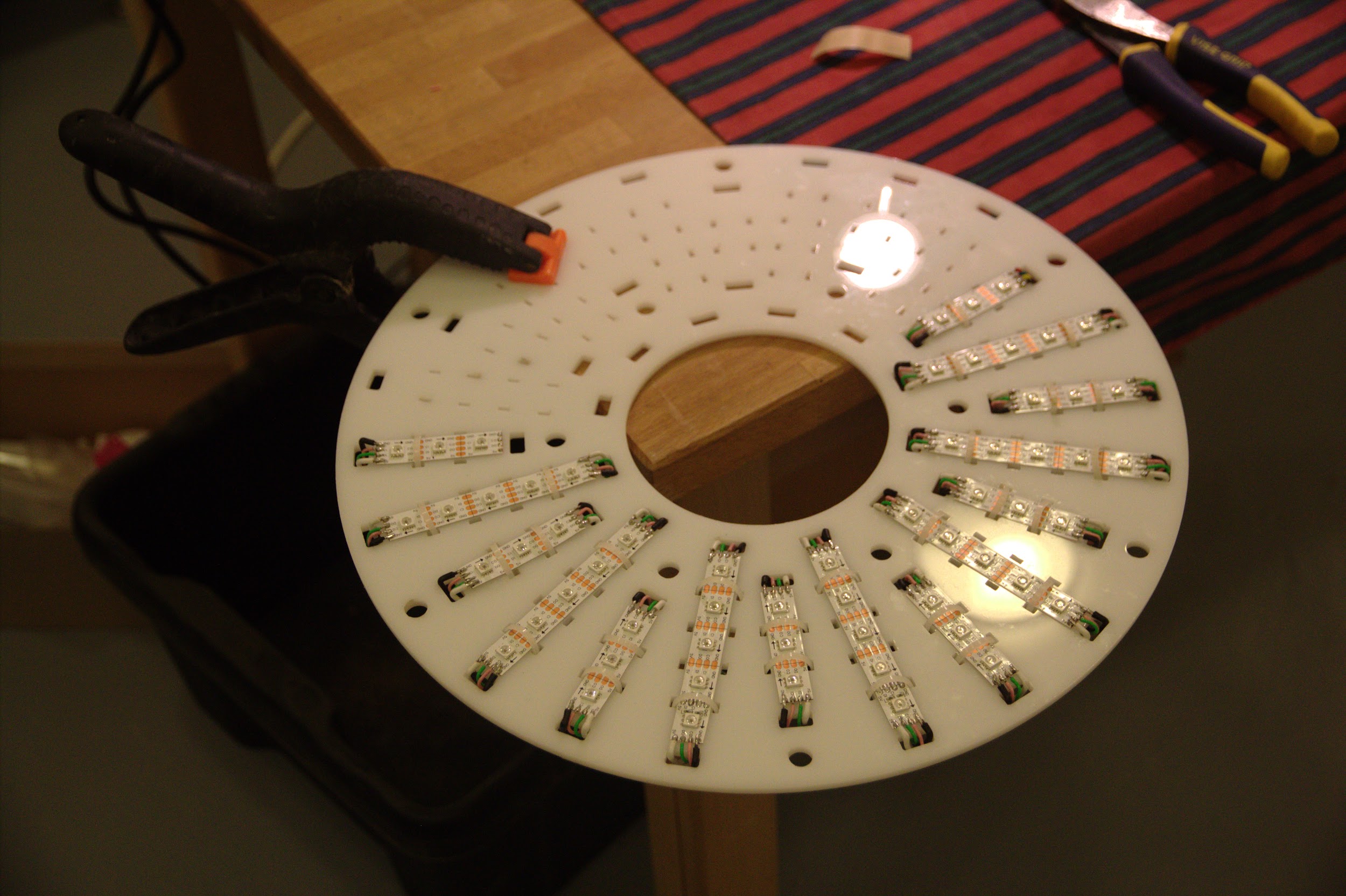

The Perspex was moved around the corner of the table when strips went over halfway around

The Perspex was moved around the corner of the table when strips went over halfway around

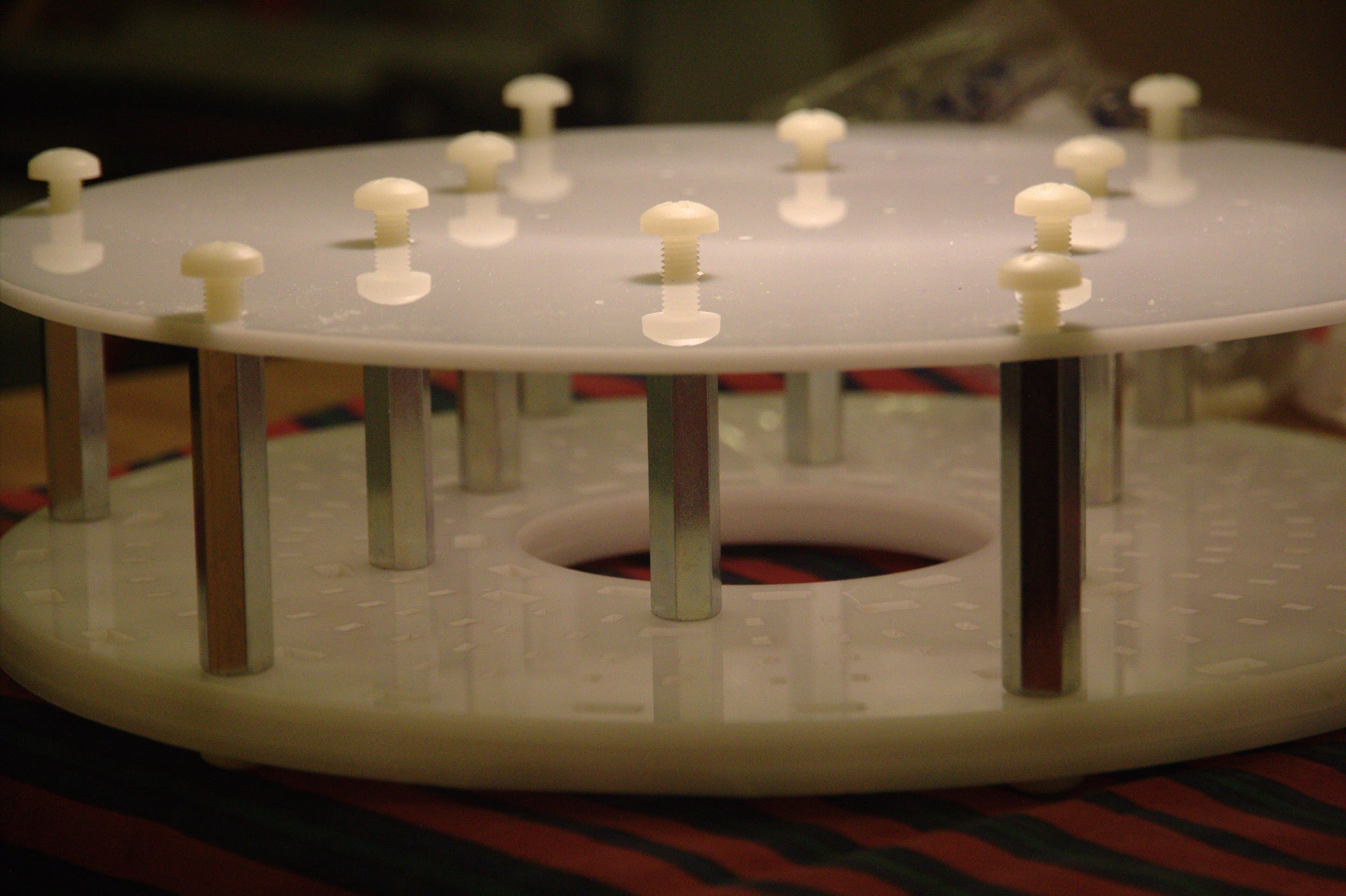

Accessing the top and bottom of the Perspex, in order to attach the remaining segments, was

achieved after unclamping it from the tabletop by connecting a number of spacers it could

balance on

Accessing the top and bottom of the Perspex, in order to attach the remaining segments, was

achieved after unclamping it from the tabletop by connecting a number of spacers it could

balance on

The upper sections after all the LED strips were connected

The upper sections after all the LED strips were connected

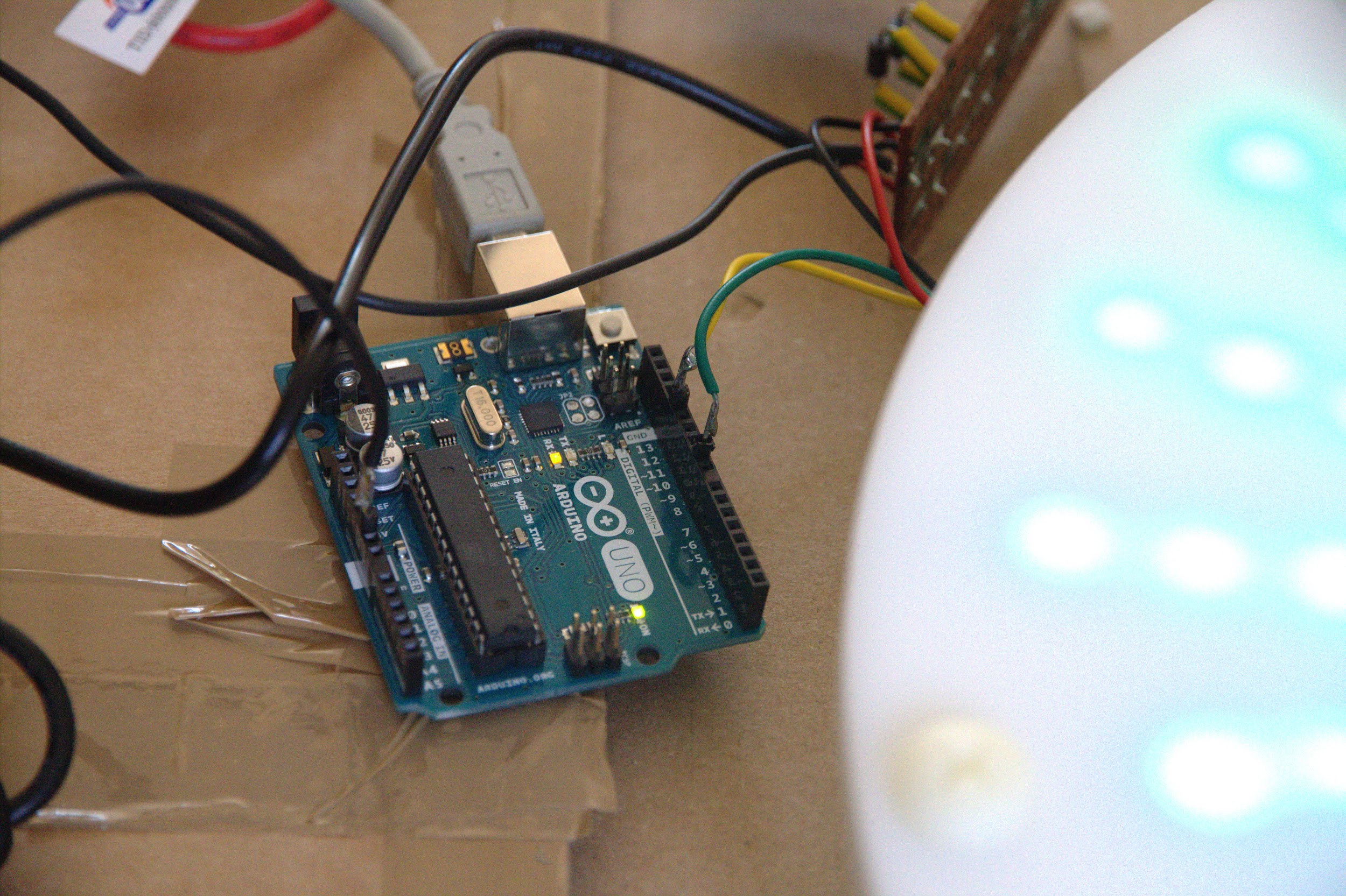

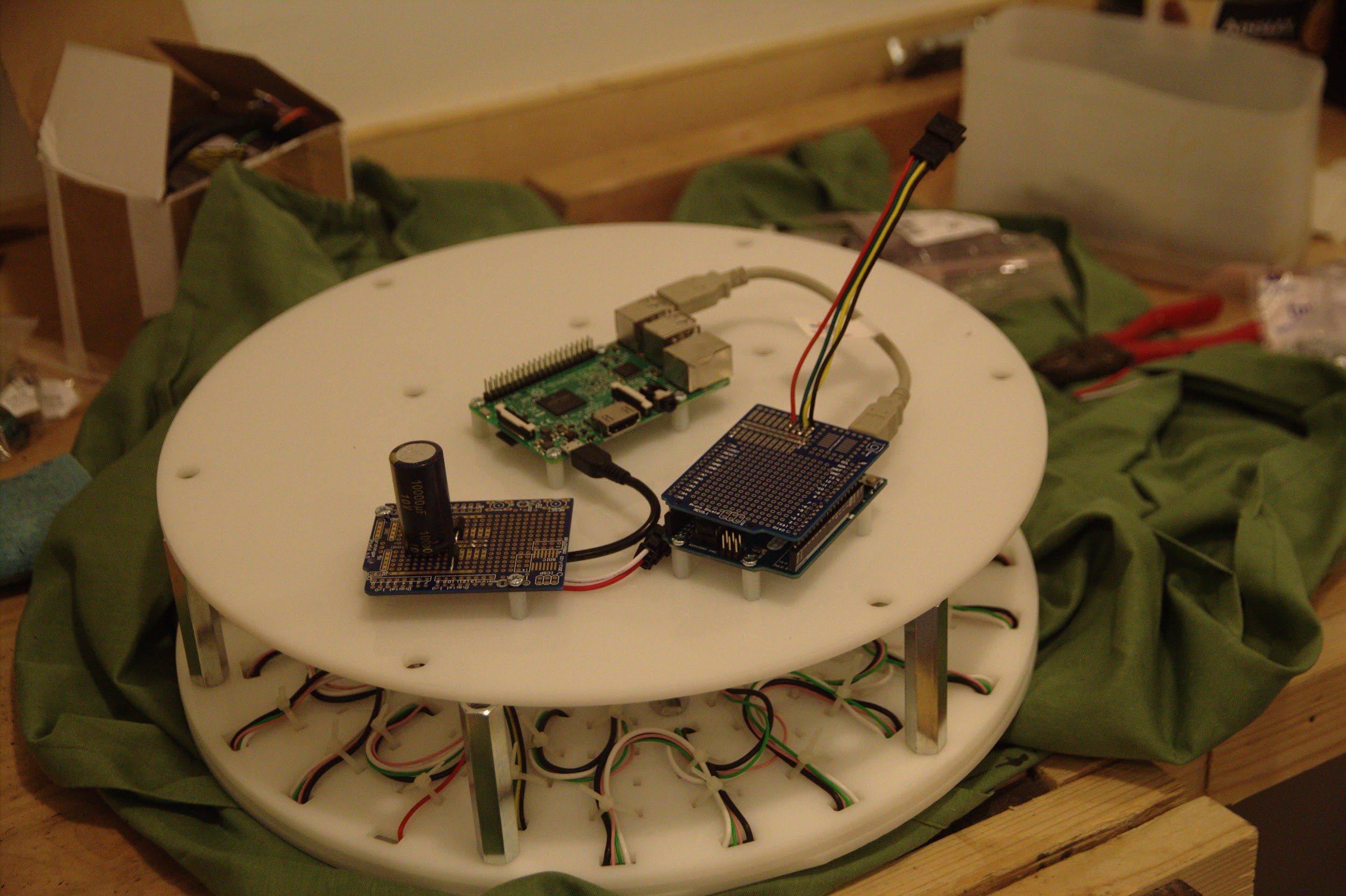

Electronics from the prototype hooked up to the new newly finished LED-plate

Electronics from the prototype hooked up to the new newly finished LED-plate

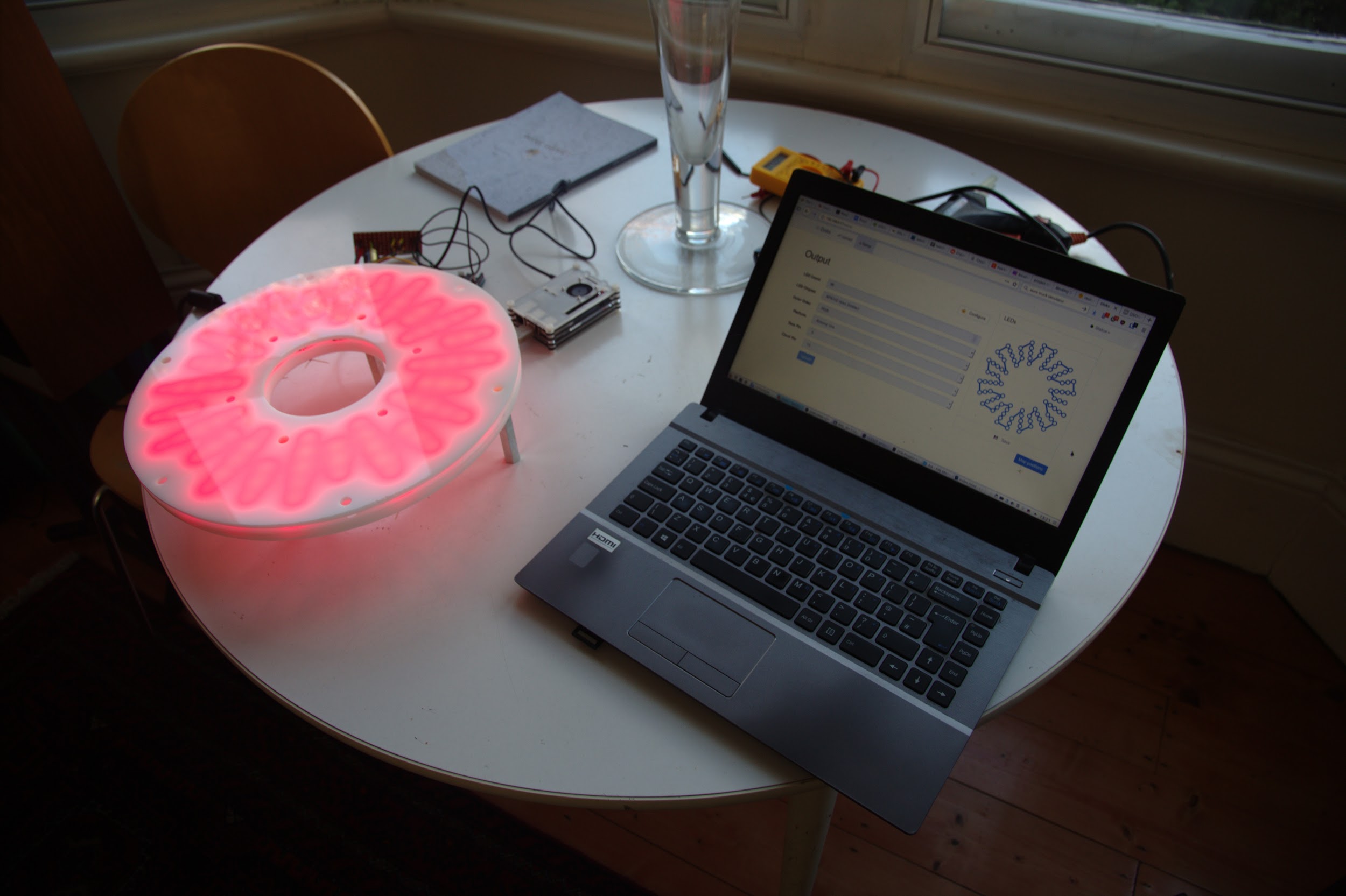

Lighting up the configured display for the first time to check it works

Lighting up the configured display for the first time to check it works

Tightened zip ties on the component’s underside

Tightened zip ties on the component’s underside

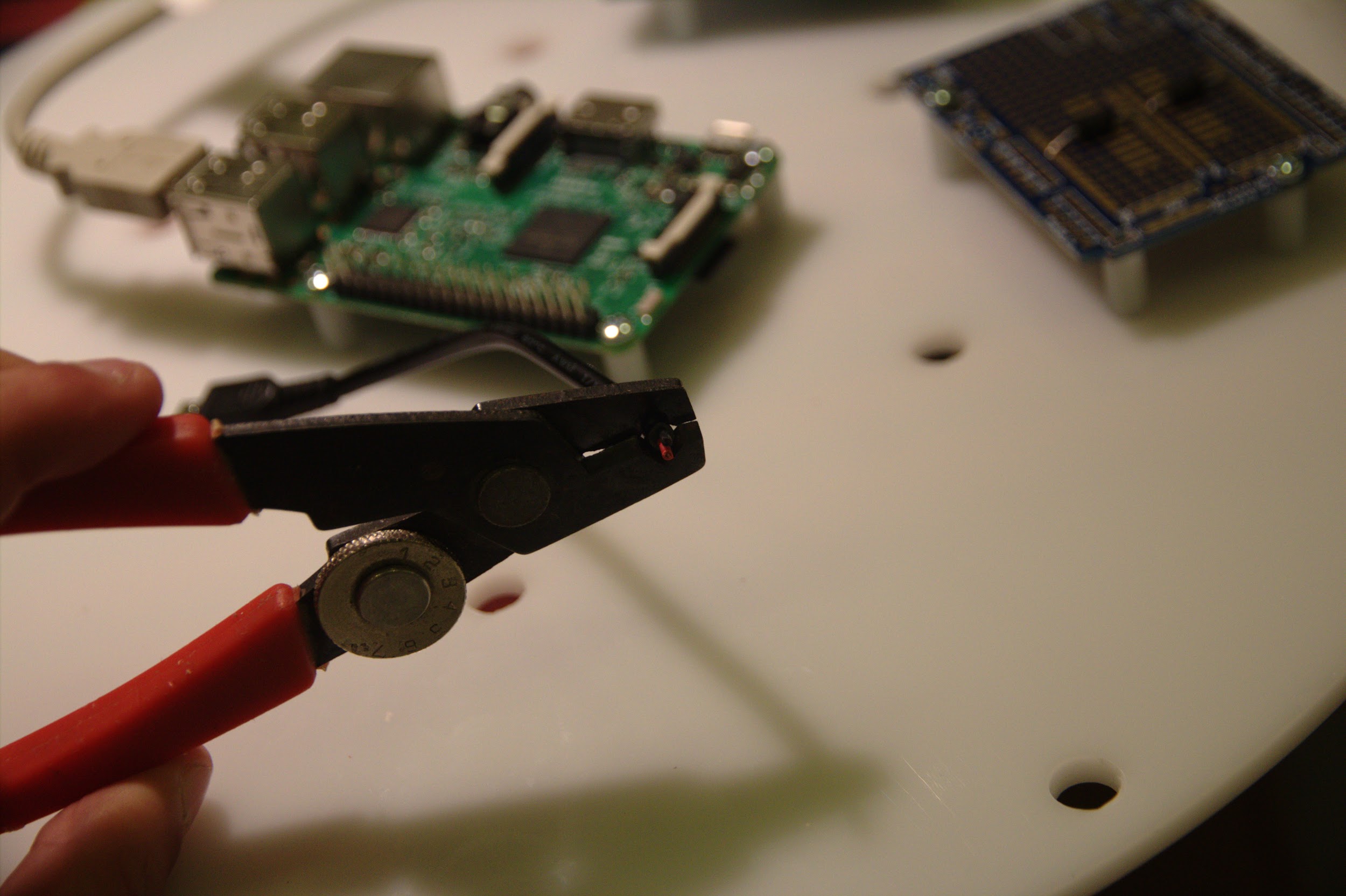

Clipping excess plastic off the secured zip ties to make space for parts to fit below

Clipping excess plastic off the secured zip ties to make space for parts to fit below

Experiment to control the LEDs using previously untested Arduino pins for data and clock,

knowing they worked gave more flexibility in the upcoming circuit design

Experiment to control the LEDs using previously untested Arduino pins for data and clock,

knowing they worked gave more flexibility in the upcoming circuit design

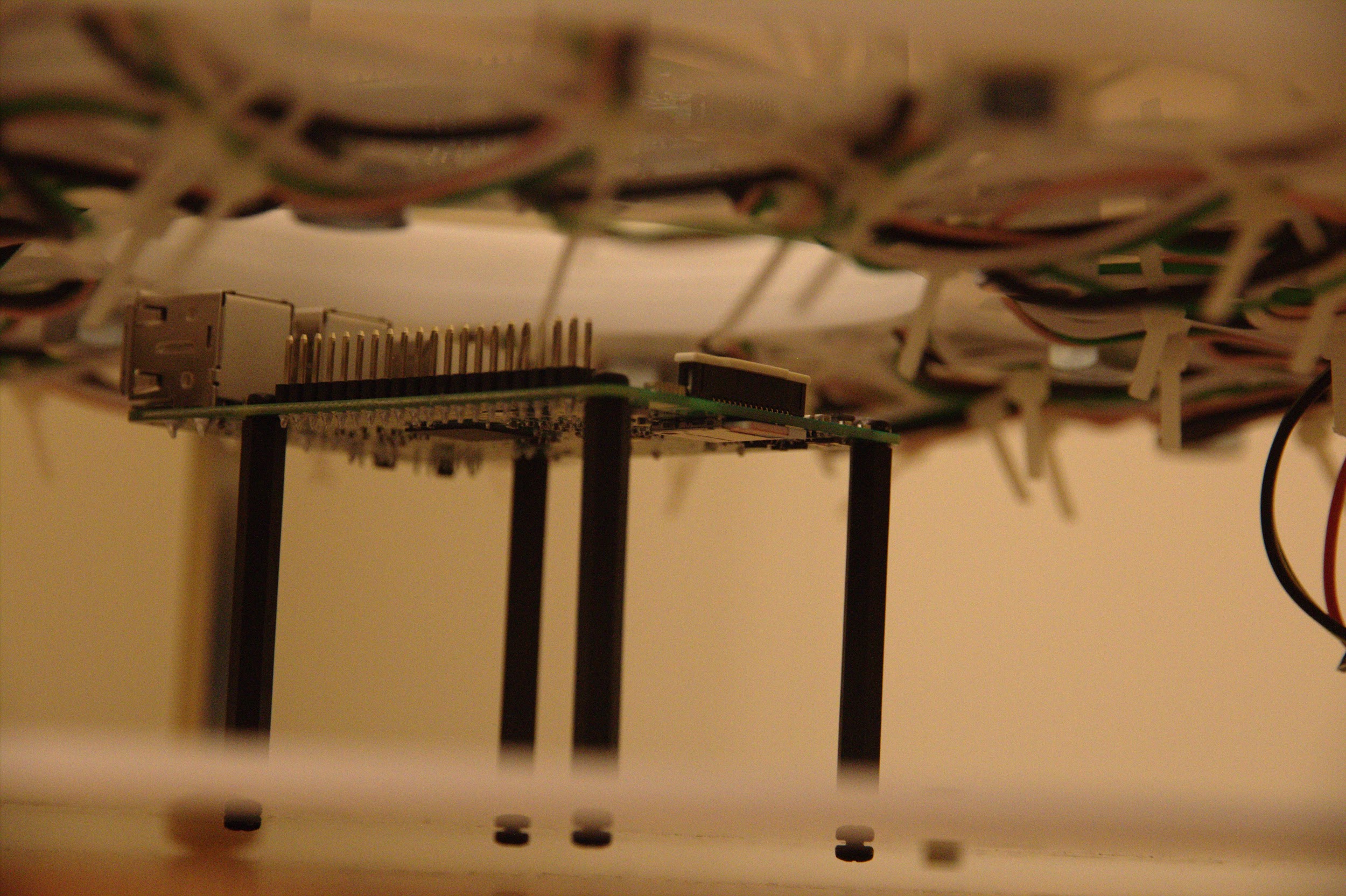

The originally planned RPi mounting solution brought the Pi close to the LEDs but held it weaker

in position

The originally planned RPi mounting solution brought the Pi close to the LEDs but held it weaker

in position

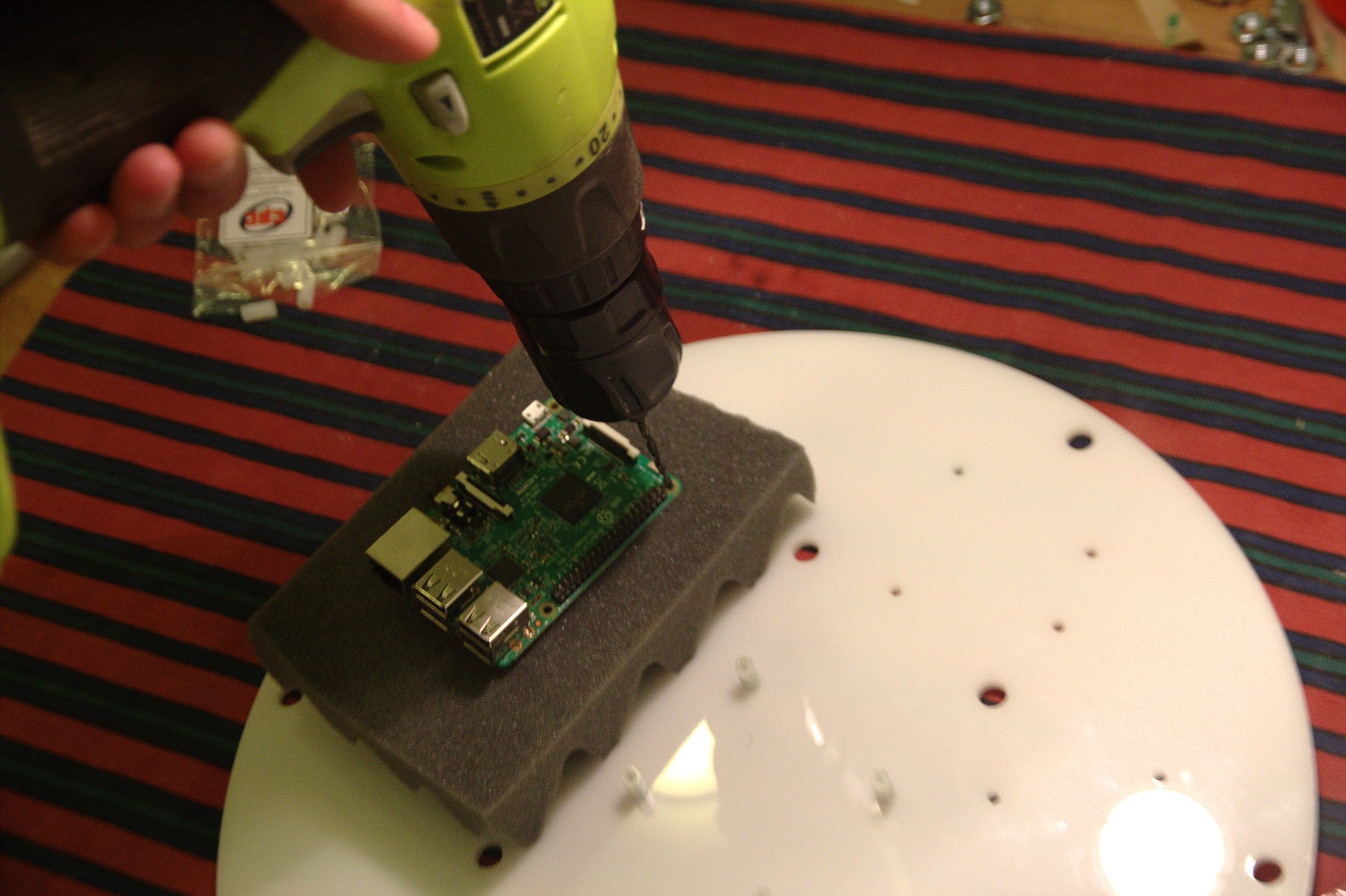

Drilling to widen the RPi mounting holes so it could be mounted on the same level as the

Arduino

Drilling to widen the RPi mounting holes so it could be mounted on the same level as the

Arduino

RPi dust leftover (the holes were only expanded by a tiny amount in reality)

RPi dust leftover (the holes were only expanded by a tiny amount in reality)

Drilling into the existing RPi mounting holes in the Perspex to widen them accordingly

Drilling into the existing RPi mounting holes in the Perspex to widen them accordingly

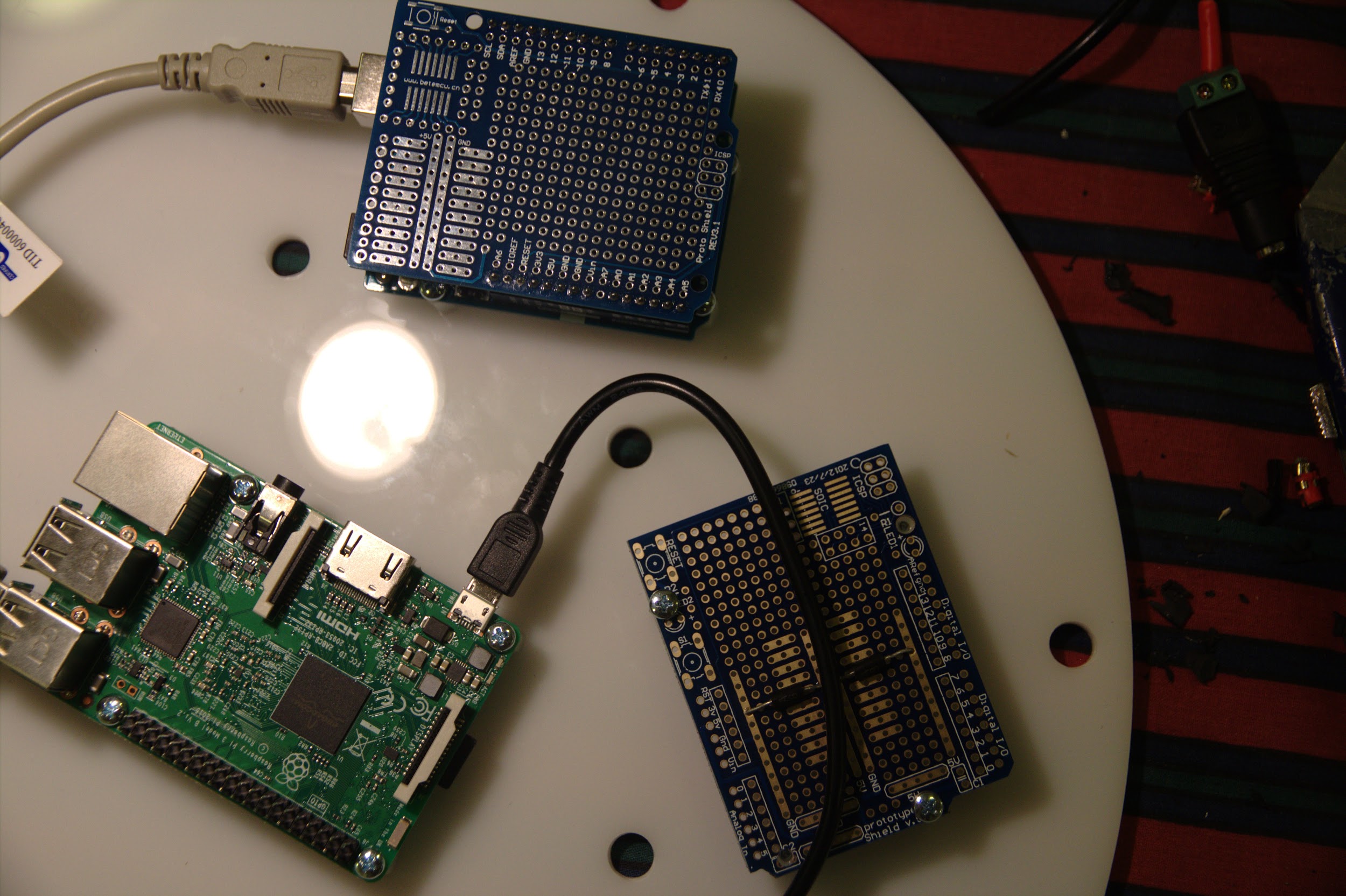

Circuit boards in their final mounting positions on the Perspex (RPi is green in the centre with a

cable attached to the Arduino, and the protoboard for delivering power is separate below)

Circuit boards in their final mounting positions on the Perspex (RPi is green in the centre with a

cable attached to the Arduino, and the protoboard for delivering power is separate below)

Voltage regulators desoldered from the earlier prototype and pliers to tightly bend their legs at

right angles before re-soldering them into position in the adjacent board

Voltage regulators desoldered from the earlier prototype and pliers to tightly bend their legs at

right angles before re-soldering them into position in the adjacent board

Simulating the MicroUSB feeding power to the RPi to estimate the length of cable to cut

Simulating the MicroUSB feeding power to the RPi to estimate the length of cable to cut

Stripping off both ends of the MicroUSB cable before tinning the wire

Stripping off both ends of the MicroUSB cable before tinning the wire

The first parts to be soldered to the power delivery board: voltage regulators and the MicroUSB

cable

The first parts to be soldered to the power delivery board: voltage regulators and the MicroUSB

cable

Mounted power delivery board with the capacitor and LED power connector soldered

Mounted power delivery board with the capacitor and LED power connector soldered

Power connections in place, including the side of LED power that is attached to a ‘shield’

protoboard on the Arduino

Power connections in place, including the side of LED power that is attached to a ‘shield’

protoboard on the Arduino

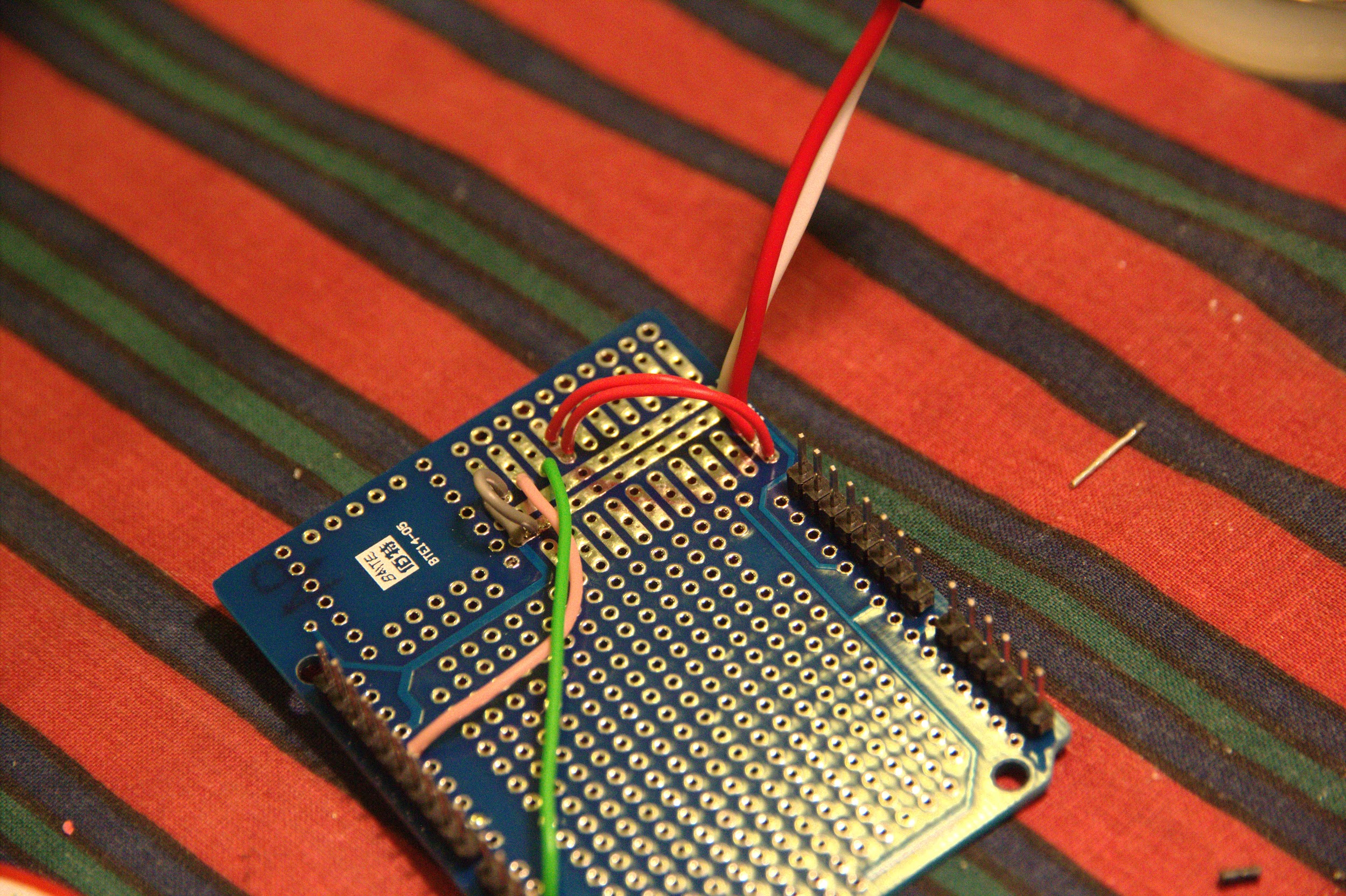

Links on the Arduino shield from the power, data and clock pins to where the LED connector will

go

Links on the Arduino shield from the power, data and clock pins to where the LED connector will

go

Finished electronics for the physical piece with the LED connector (extruding above the

Arduino) that fits into a single connector to the actual LEDs hidden below

Finished electronics for the physical piece with the LED connector (extruding above the

Arduino) that fits into a single connector to the actual LEDs hidden below

Media uploaded on the web app being displayed on the finished object

Media uploaded on the web app being displayed on the finished object